Basic Fact Pattern

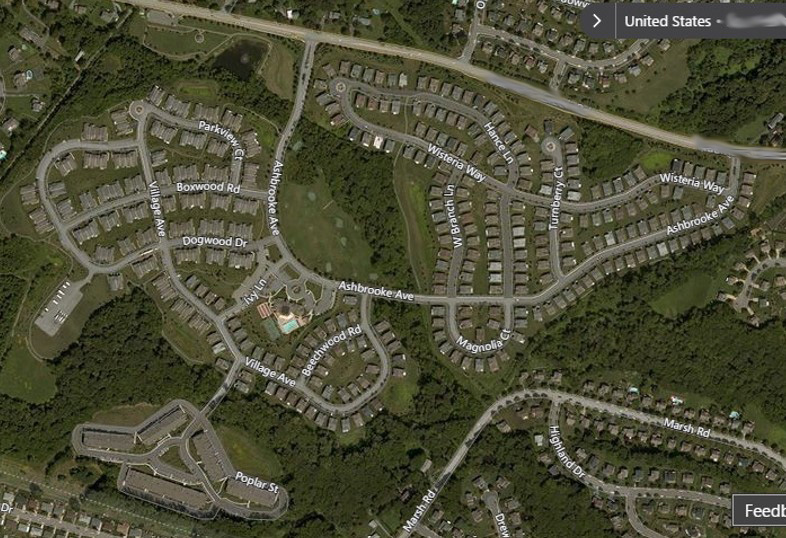

- Development of 250 units, including a clubhouse building, townhomes, and single family residences.

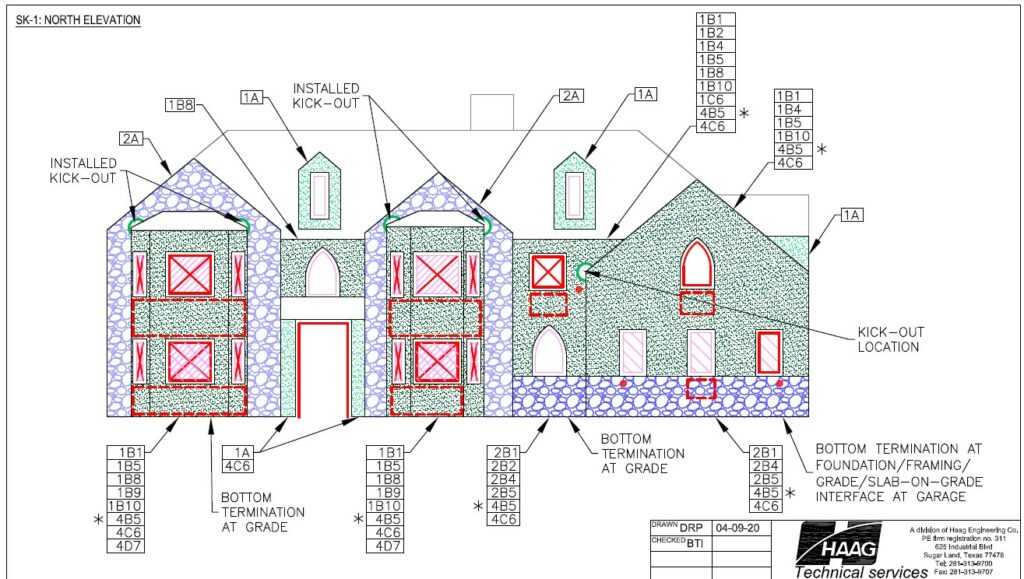

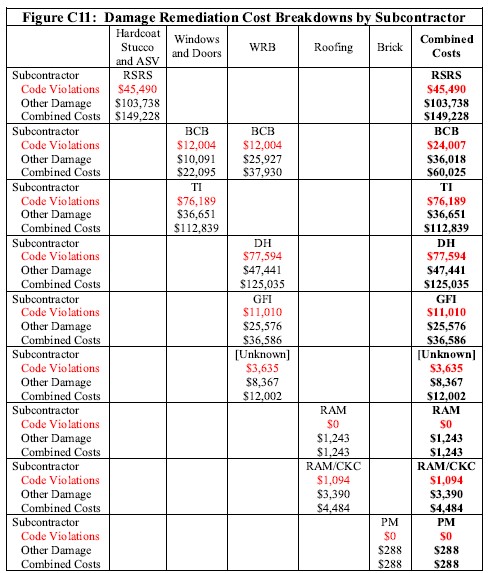

- Alleged construction defects in the exterior claddings resulting in systemic moisture intrusion and underlying structural damage.

- Exterior claddings consisted of combinations of vinyl siding, hardcoat stucco, and adhered stone veneer.

- Alleged damages included complete re-cladding of all buildings.

Investigative Sciences Employed

- All 250 buildings were visually inspected.

- Moisture probe tests were performed on a representative sampling of buildings of each type.

- Destructive test cuts were performed and a separate representative sampling of buildings of each type.

- Detailed analyses of opposing expert investigational methods were performed.

- Comprehensive code analysis was performed across the three building codes represented across the timeframe of construction for the differing phases of the development.

Determinations Made

- Actual moisture intrusion was minimal, localized, isolated, and associated with discrete, non-systemic causes.

- Complete exterior re-cladding was not required.

- A remedial action plan was developed, along with a cost to perform the repairs.

- Litigation support services were also provided throughout alternative dispute resolution.

Involved Experts: