Research & Testing in action: A dog’s story

By Steve Smith, PE, Forensic Engineer, Director of Research & Testing

In 2018, Haag Research & Testing expanded our testing capabilities by acquiring a Heat Flow Meter (HFM) and adding ASTM C518 Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Apparatus to our laboratory accreditation. The HFM gave us the ability to measure the R-value (thermal resistance to conductive heat flow) of insulation. Since that time, we’ve used the HFM to measure the R-value of roof insulation, artificial athletic track surfacing, insulation for medical equipment, experimental insulation formulations, and even wall panels.

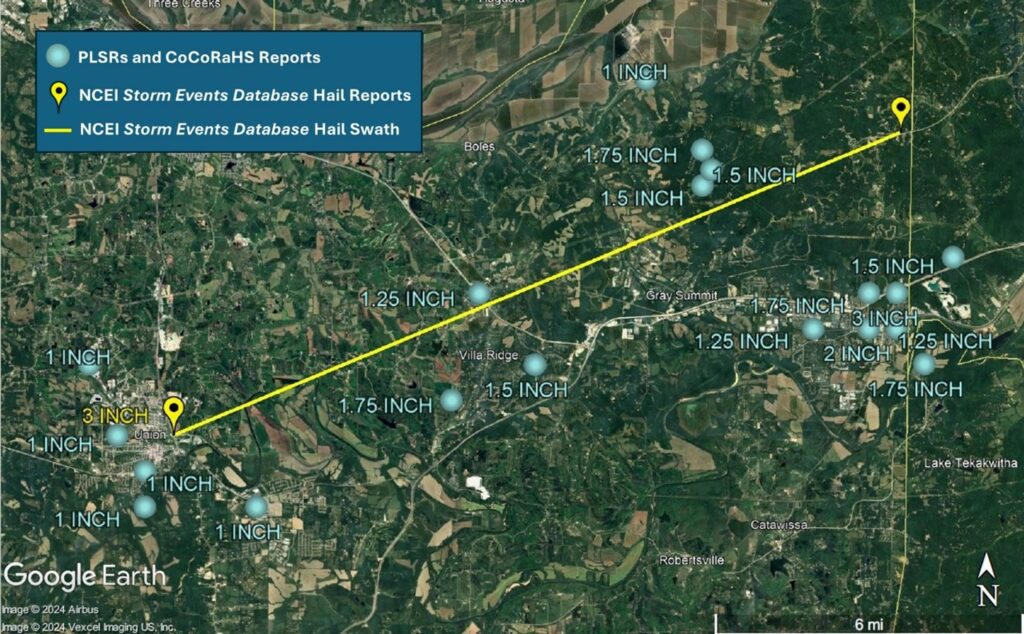

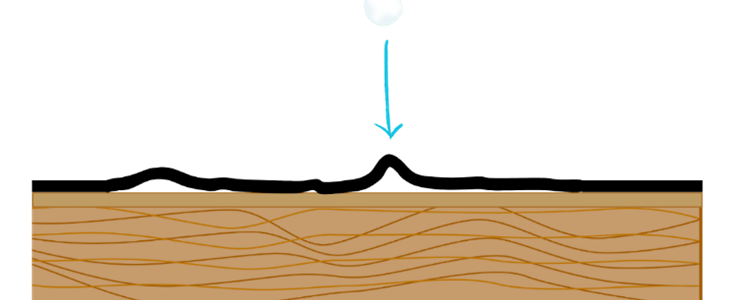

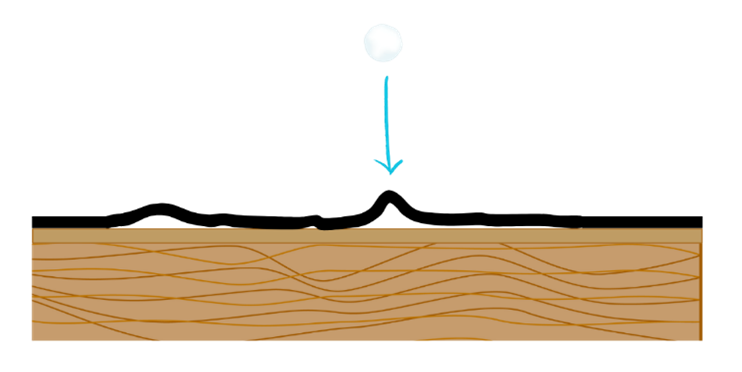

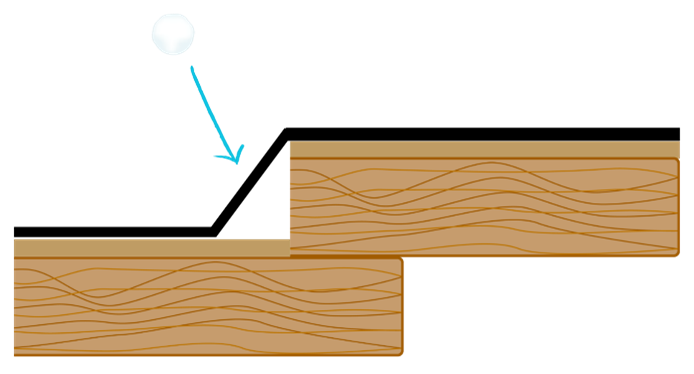

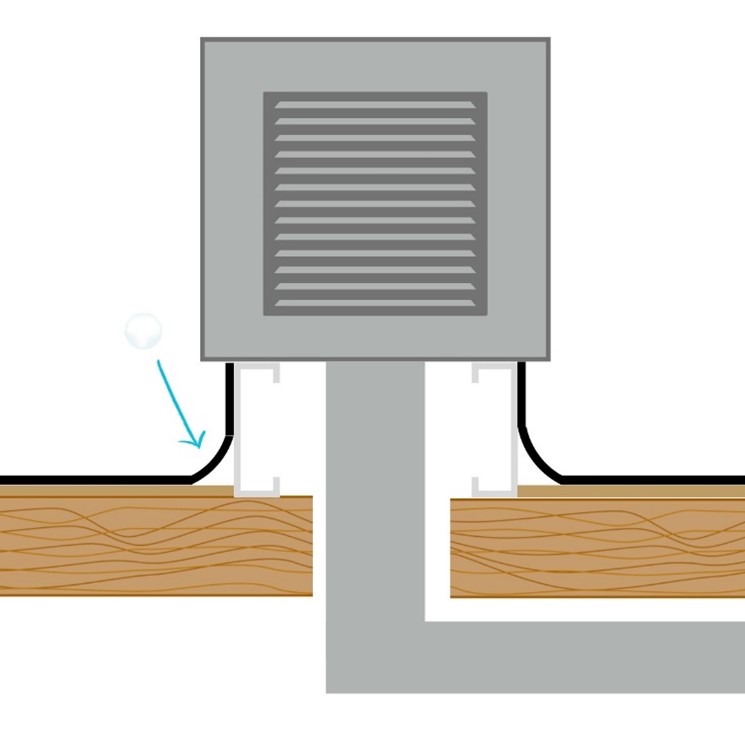

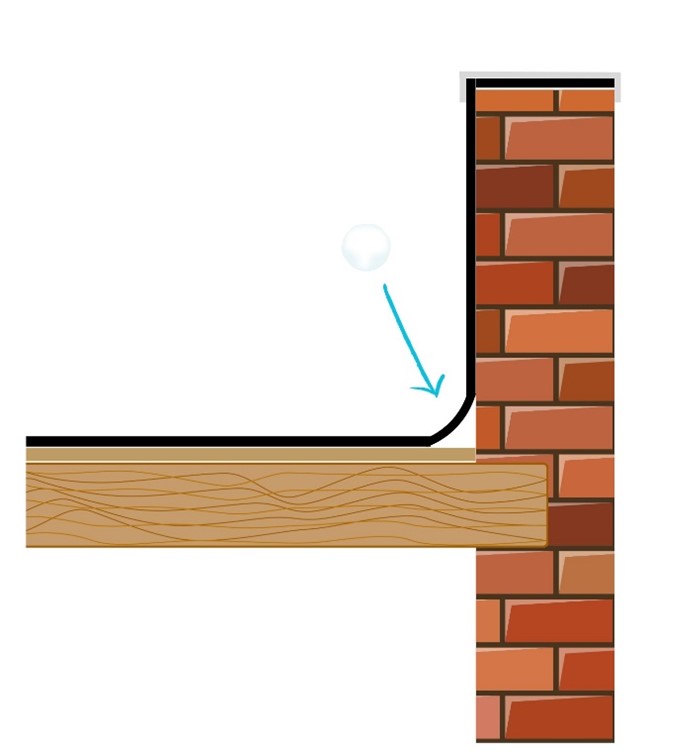

We also used the HFM to conduct a research study on the effects of hail-caused dents on the thermal performance of insulation under single-ply roofing. Our research paper for the study can be found here.

Earlier this year, we were contacted by an entrepreneur, Leena Chitnis, who invented a special dog bed that was designed to keep her recently adopted rescue dog warm while camping in cold weather. The bed combines thermal insulation to insulate her little Kashi from the cold ground and a detachable sleeping bed cover to keep cold air off Kashi while sleeping at night. Leena was so excited to finally find a laboratory that was willing to test the dog bed so that she could provide data to her customers and in hopes of being highlighted on a popular celebrity investor show on network TV in the coming season. A few months before being contacted by Leena, we lost our little Shizu “Ranger” to illness and offered to test the dog bed free of charge to help Leena with her dog bed project and to honor our little buddy.

Okay, enough about Mr. Ranger.

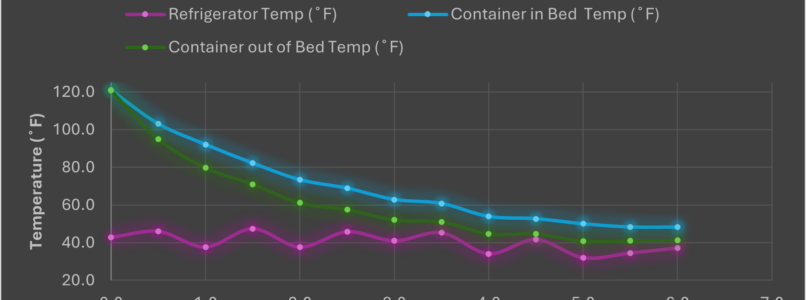

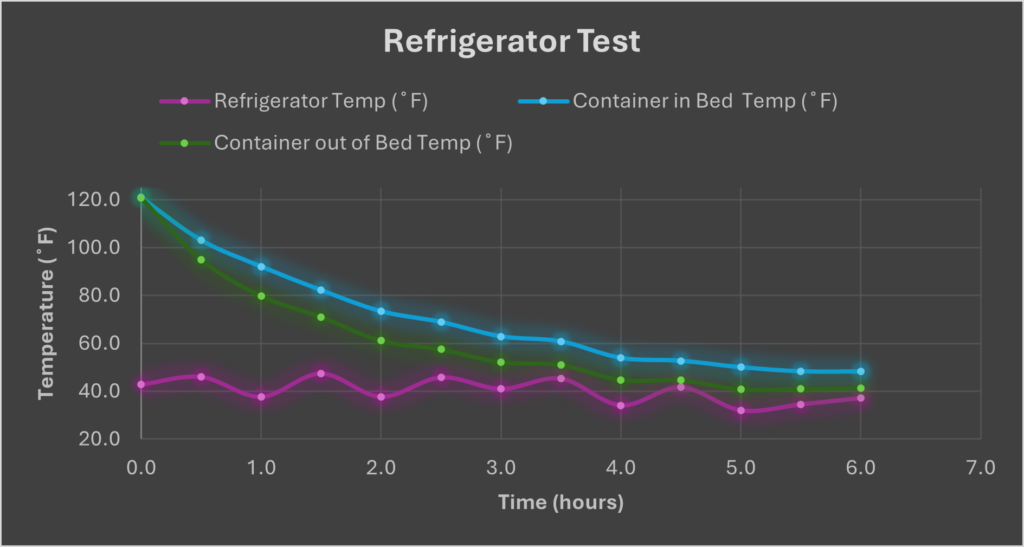

Our testing of the RuffRest Ulimate Dog Bed (patent pending) demonstrated the sleeping bag helped retain body heat and the R-value was more than adequate to insulate dogs from the cold ground. We give Leena, Kashi, and all other camping dogs our best wishes, and hope they stay warm while camping this winter and many winters to come.

Learn more about Leena’s RuffRest Ultimate Dog Bed here- www.timberdog.com.

If you have a testing project, contact Haag to see how we can help.

STEVE SMITH, P.E., DIRECTOR OF RESEARCH & TESTING, PRINCIPAL ENGINEER

Steven R. Smith is a Forensic Engineer with Haag Engineering Co., and the Director of Research & Testing. Mr. Smith is an experienced forensic engineer who began his career with Haag more than 24 years ago. He spent seven years working as a Senior Lab Technician while earning a Bachelor of Science in Mechanical Engineering degree from The University of Texas at Arlington. He has been involved with the lab throughout his career, and has been able to leverage his extensive and practical engineering field experience with research and testing projects.

Mr. Smith’s areas of expertise include accident reconstruction, mechanical equipment evaluations, code and standards compliance, roofing system evaluations, and fires and explosions. He is a licensed Professional Engineer in Arkansas, Minnesota, Missouri, Oklahoma, Texas, and Wisconsin. He is a member of the American Society of Mechanical Engineers (ASME), Society of Automotive Engineers (SAE), and Pi Tau Sigma National Honor Society. Prior to joining Haag, Mr. Smith was a Petty Officer Second Class in the United States Navy. He trained at the Navy Nuclear Power Training Command Center in Orlando Florida and was stationed on the USS Arkansas (CGN-41), where he maintained reactor and steam plant chemistry, performed radiological controls, and operated mechanical equipment in the propulsion plant.

Any opinions expressed herein are those of the author(s) and do not necessarily reflect those of Haag Technical Services, Haag Engineering Co., Haag Education, or parent company, Haag Global, Inc.