November Newsletter- “Seen and Unseen – The Benefits of Desaturation Testing”

Month: November 2018

November 2018 Blog

Seen and Unseen….The Benefits of Desaturation Testing

By Steve R. Smith P.E.

Have you ever been examining a built-up roof and encountered a mark which was not easy to identify? Identification of hail-caused damage to a roof can be as simple as following standard hail inspection procedures. Look for hail spatter and dents in soft metals. Examine less well supported components and examine test areas on the roof (a procedure developed by Haag Engineering Co. in the 1970s).

Sometimes, however, there are conditions observed on the surface of the roof that appear similar to a hail-caused condition but may or may not be related to hail. Also, it is not uncommon for two separate parties to have differing opinions on whether or not a hail-caused condition has compromised the roof covering.

When you find questionable marks on a roof, desaturation analysis of roofing samples can provide invaluable information. Desaturation can help determine if a particular feature is hail-caused and if the water-shedding ability or long-term service life of a roof has been compromised. Haag Engineering’s laboratory, established in 1963, has been performing desaturation analysis on roofing samples for decades. Desaturation can determine conclusively if a bituminous roofing sample has been compromised by hail.

Desaturation works like this: lab personnel use equipment and chemicals to extract the reinforcements from asphalt built-up roofing (ABUR), coal tar built-up roofing (CTBUR), modified bitumen membranes (mod-bit), asphalt roll roofing, and asphalt shingles. Then, they examine the reinforcements to identify fractures, or the absence of fractures, and determine if the fractures present are characteristic of damage associated with hailstone impacts. Desaturation can also help identify the constituents of a roof, including the number of roofing plies, the types of roofing plies, and the quantity (weight) of the inter-ply asphalt.

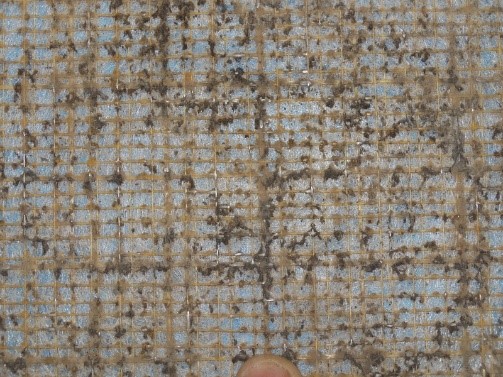

Haag’s lab examined an ABUR sample for the effects of hail, see photos below. When the bitumen was removed, our analysis revealed fiberglass reinforcements from the ABUR system, and several organic reinforcements from the previous roof system that was left in place and overlaid. There were no hail-caused fractures in the fiberglass reinforcements, but a hole was observed in one of the organic plies. We noted the hole was only present in the uppermost organic ply, which is not consistent with an impact-caused fracture. Instead, the hole was characteristic of a weathering-related condition in the older roof system.

Figure 1: Desaturation of ABUR – fiberglass and organic reinforcements

ABUR prior to desaturation

|

ABUR after desaturation showing

fiberglass reinforcement

|

Organic reinforcement was found

several piles down, revealing a hole

|

Hole was found in the

uppermost organic ply only |

Organic ply below the top organicply did not contain a hole,indicating the hole was a weathered condition on the oldroof, rather than an inpact-caused fracture

|

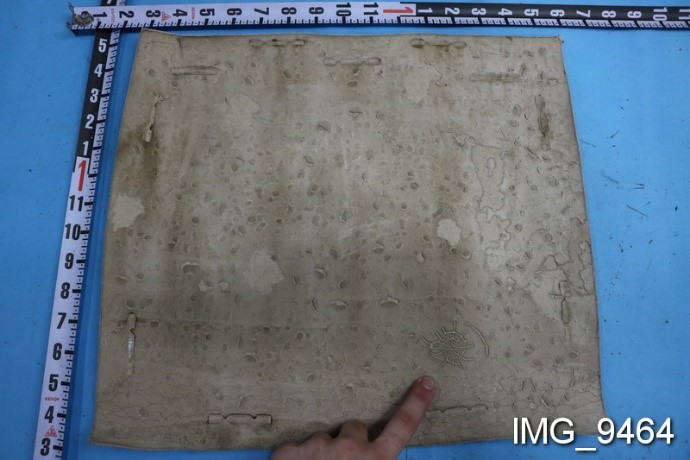

Now let’s look at a mod-bit sample. This sample exhibited a discrete region of missing granules that was thought by some to be a hail-caused bruise. There were no fractures visible in the top or bottom surfaces of the sample prior to desaturation. We noted the exact location of the area of interest so that we could examine the same area after desaturation, which revealed the reinforcement was intact.

Figure 2: Desaturation of mod-bit – scrim-type reinforcement

Mod-bit prior to desaturation

|

Area of interest observed on

the top surface

|

Scrim-type reinforcement extracted by desautration Scrim-type reinforcement extracted by desautration |

Close-up of reinforcement at the area of interest revealed no damage to the reinforcement (the structural element of the roof)

|

Finally, let’s examine a mod-bit sample that shows the effects of impact by large hail. Our laboratory personnel installed a mod-bit sample on a test panel to replicate the as-installed support conditions for the sample and performed ice ball impact testing to show the effects of hail impact. The sample was impacted by three ice balls, ranging up to two inches in diameter. The two-inch diameter impact is highlighted in blue (Figure 3). Desaturation of the sample revealed a fracture at the two-inch diameter impact location.

Figure 3: Desaturation of mod-bit impacted by ice balls – polyester reinforcement

Mod-bit prior to desaturation

|

Impact testing setup

|

Sample after impact testing

|

Sample after desaturation (top side up)

|

Bottom side of reinforcement

after desaturation

|

Close-up at fracture caused by a

2-inch diameter ice ball impact

|

In all examples, desaturation was able to conclusively determine if the reinforcements had been fractured by hail. Desaturation also allowed us to identify constituent components and even provided insight on the condition of the previous roof system (Figure 1). Hail-fractured reinforcements ultimately result in a loss of water-shedding ability and/or reduction of the remaining service life of the roof. Knowing if the structural components of a roof had been compromised by hail is paramount in determining appropriate remediation procedures.

Since desaturation is destructive testing, Haag Research and Testing personnel carefully document test specimens during all phases of testing. We photograph and even video record (if requested) to document specimen conditions and preserve the evidence. Proper maintenance of the chain of custody of evidence is another important consideration.