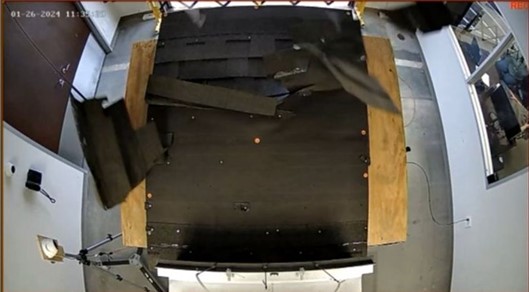

Generator May Be Missing Heat ShieldFlooring material exposed to heat increases the risk of fire and injury.

NHTSA Campaign Number: 24V314000

Manufacturer Airstream, Inc.

Components EQUIPMENT

Potential Number of Units Affected 8

Summary

Airstream, Inc. (Airstream) is recalling certain 2023-2024 Atlas motorhomes. The generator may have been installed without a heat shield, which can expose the subflooring to excessive heat.

Remedy

Dealers will install the heat shield above the generator, free of charge. Owner notification letters are expected to be mailed July 2, 2024. Owners may contact Airstream customer service at support@airstream.com, 1-877-596-6505 or 1-937-596-611 ext. 7401.