Impact Resistant Shingles

In May 2019, Haag Research & Testing Co. (HRT) published the blog for the Haag Global newsletter which discussed the history of simulated hail testing performed by Haag over the years. We also explained our current ice ball launching platform (the IBL-7) and mentioned two impact testing protocols used to classify the impact-resistance of roofing products. (The blog can be viewed here.)

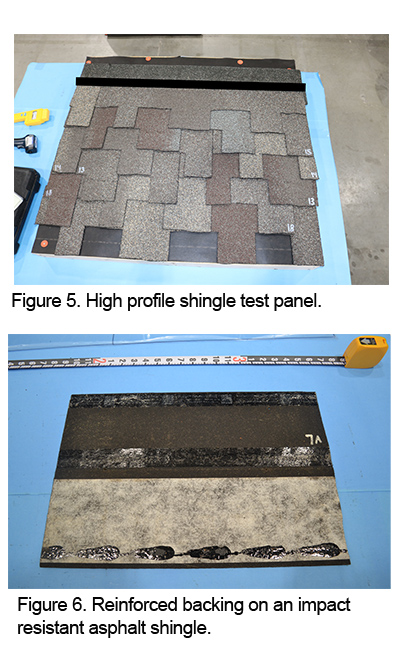

Since then, HRT conducted a research project to put several impact-resistant roofing products to the test. Five asphalt shingle designs from four different manufacturers were tested against their published impact ratings to determine if they would perform as advertised. Although two of the five shingles performed consistent with their ratings, the study revealed an important shortcoming in the impact testing standards. Test standards UL 2218 (steel ball drop test) and ANSI/FM 4473 (propelled ice ball test) specify visual examination of the tested roofing products after testing to determine if the products were compromised by the impacts. These test standards do not currently evaluate the reinforcements within asphalt shingles or other bituminous roofing types. Consequently, reinforcements can be fractured or strained during impact testing, yet go unnoticed by laboratory personnel performing the tests.

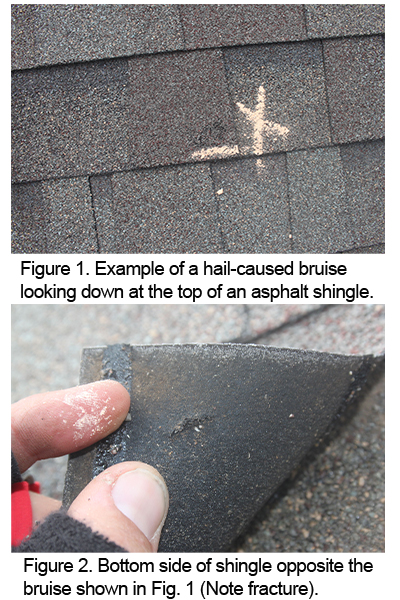

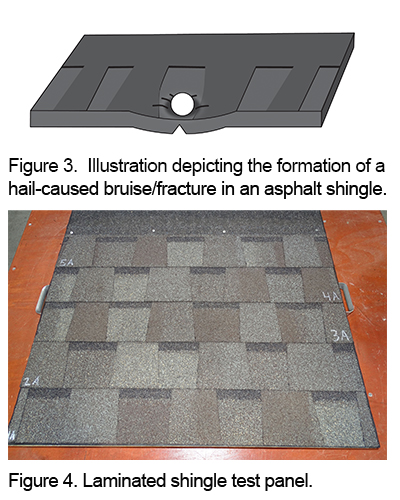

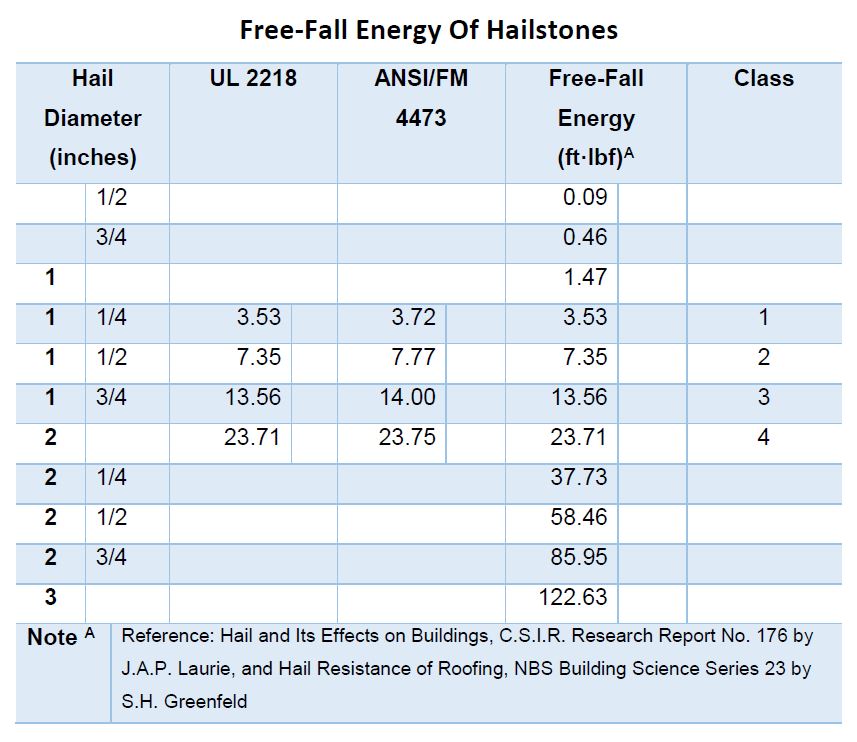

HRT not only tested the impact-resistant shingles according to both testing protocols, but also extracted the shingle reinforcements using hot solvent, a process called “desaturation testing”, after the impact testing was completed. The desaturation process not only revealed impact-caused fractures in all five of the tested shingle designs at their published class ratings, but also found fractures in their reinforcements from impacts at lower class ratings, including Class 1, which is the lowest rating. Class 1 tests involve steel balls or ice balls that impact test specimens at energies similar to the free-fall energy of hailstones measuring 1-1/4 inches in diameter. It is important to understand, the kinetic energy of a hailstone increases exponentially with size. The table below summarizes the kinetic energy of free-falling hailstones and includes the kinetic energies of Classes 1, 2, 3, and 4 outlined in UL 2218 and ANSI/FM 4473 test standards.

Four of the five shingle designs had an additional reinforcement layer, strategically placed on the back sides of the shingles which should increase the tensile strength of the shingles. The reinforcement backing, however, obstructed the view of fractures in many cases during the study, causing the visual examinations described in the tests to fall short of ascertaining the true performance of the shingles.

Desaturation testing is described in ASTM D3746 (Standard Test Method for Impact Resistance of Bituminous Roofing Systems), which is a long-standing test procedure for determining the impact resistance of asphalt built-up roofing (ABUR). HRT performs desaturation testing during forensic examinations of roofing involved in insurance claims or legal disputes and has done so for decades. HRT is accredited by the International Accreditation Service (IAS) to perform desaturation testing and both UL 2218 and ANSI/FM 4473 impact testing protocols. HRT has the capability to propel ice balls ranging from 1/2 inch up to 4 inches in diameter, providing useful information outside the range of the ANSI/FM 4473 ice ball testing protocol. Impact testing with simulated hailstones and utilization of desaturation procedures are often performed together to gain an accurate understanding of the impact resistance of roofing products, surface conditions caused by hail, and whether or not bituminous roofing samples taken from roofs for forensic evaluations have sustained hail-caused fractures or strains in their reinforcements. Bituminous products suitable for this type of testing include asphalt shingles, ABUR, modified bitumen membrane roofing, and coal tar built-up roofing.

The study of impact-resistant shingles performed by HRT has been peer-reviewed, and was published in the May 2020 edition of Interface Magazine (Source: https://iibec.org/). The article can also be viewed here.

Read Haag’s White Paper: Impact Testing of Impact Resistant Shingles here.

Steve R. Smith, P.E., completed nuclear power training with the United States Navy in 1994. He was honorably discharged in 1998 and went to work for Haag Engineering Co. as Senior Laboratory Technician. Steve has performed hundreds of hail impact tests on a variety of products including roofing, siding, and automobiles. He graduated from the University of Texas at Arlington in 2005 with a Bachelor’s degree in Mechanical Engineering and is a member of the American Society of Mechanical Engineers, the Society of Automotive Engineers, and the National Association of Fire Investigators. Steve has inspected and assessed damage to a number of roof systems, including single-ply systems, composition shingles, cedar shake and shingles, concrete tiles, slates, and built-up roofing. As Director of Research & Testing, Mr. Smith oversees all testing projects, protocols and manages Haag’s accreditation. Mr. Smith is based at Haag’s national headquarters in Flower Mound, TX.

Any opinions expressed herein are those of the author(s) and do not necessarily reflect those of Haag Engineering Co., Haag Construction Consulting, Haag Education, or parent company, Haag Global, Inc.