As we celebrate Haag’s 95th anniversary in 2019, we are looking back at some of the noteworthy and important projects Haag Engineers and Consultants have been involved with over the last 95 years. Each month in 2019, this blog will feature one unique, important project, as selected by our senior staff.

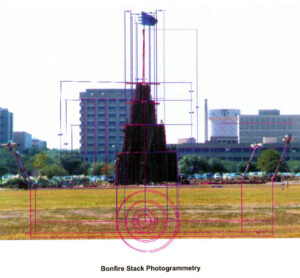

At approximately 2:42 am on November 18, 1999, the annual Aggie Bonfire at Texas A&M University in College Station, Texas, collapsed during construction, killing 12 people and injuring 27 others. Per Aggie tradition, the 59-foot-tall bonfire would have been lit on November 25th, the night before Texas A&M played football against the University of Texas.

The Texas A&M Bonfire Collapse

By Jim D. Wiethorn, Ph.D., P.E., Principal Engineer

I became involved with the Aggie Bonfire Collapse through a client, Leo Linbeck, Jr., who was the Chairman of the Special Commission on the 1999 Aggie Bonfire. I developed a relationship with Mr. Linbeck after working with him on my first crane accident with Haag in 1987, and several other projects over the years.

Mr. Linbeck called and asked if I would be interested in interviewing to perform work on the collapse, which, of course, I accepted. I attended the interview with representatives of Texas A&M, McKinsey & Company (a global management and consulting firm), and various members of the commission. After much discussion, Mr. Linbeck asked if Haag would work with McKinsey as part of the peer-review committee, tasked with reviewing work as it progressed and writing an opinion letter on the practices and procedures of the five consulting firms investigating the collapse.

The Peer Review Committee’s job was to validate the engineering approach and analytical methodology used by the engineering teams investigating the bonfire collapse. The Committee consisted of Dr. German Gurfinkel, University of Illinois, structural engineer; John W. Fowler, Fowler Engineering & Construction (designed and built Chesapeake Bay Bridge-Tunnel); Dr. Monte Phillips, University of Minnesota, geotechnical engineer; and Jim Wiethorn, Haag Engineering Co., forensic structural engineer. I was appointed Chair of the committee, and I included John Stewart, P.E., and David Teasdale, P.E., to assist in this endeavor, particularly since Haag was located in fairly close proximity to College Station while the other members were out of state.

We spent approximately four months on-site gathering information, reviewing engineering techniques, and evaluating and critiquing presentation of finding by the five teams and ultimately writing a summation of our opinion. The report was issued in April 2000 and was included in the final production of the “Texas A&M Bonfire Collapse Report”.

About a week later, a representative from McKinsey called and stated that they had decided that each commissioner would read a summation of each portion of the report. I assisted McKinsey late into the evening summarizing the results from each of the team. The following morning, the report findings were publicly presented by the commissioners at the Reed Arena.

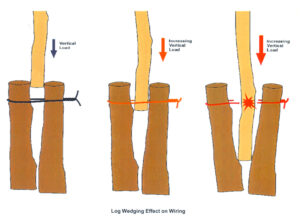

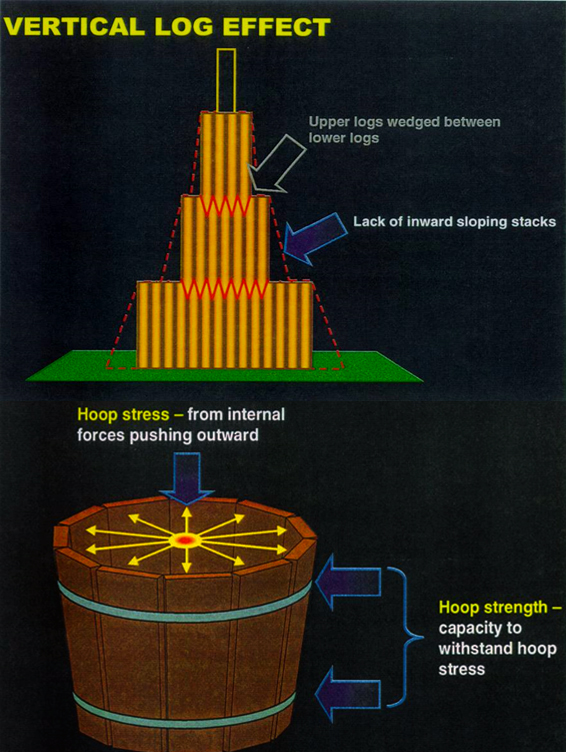

Understanding the historical development and progression of the bonfire was extremely interesting and relevant as to how and why the bonfire’s shape changed. One interesting change was from the standard straight pine logs to gnarly oak logs. Three logs were always tied together with conventional tie-wire, so the method of wire installation was actively analyzed. It was found that freshmen would do the wiring and generally just twist the end until it broke. Inserting the logs resulted in high hoop stresses that ultimately compromised the entire structure. This change materialized due to the belief of the corps that if the bonfire collapsed before midnight, they would lose the game to Texas. Therefore, the decision was made to go from pine logs to oak logs so the fire would burn longer and maintain the vertical shape longer.

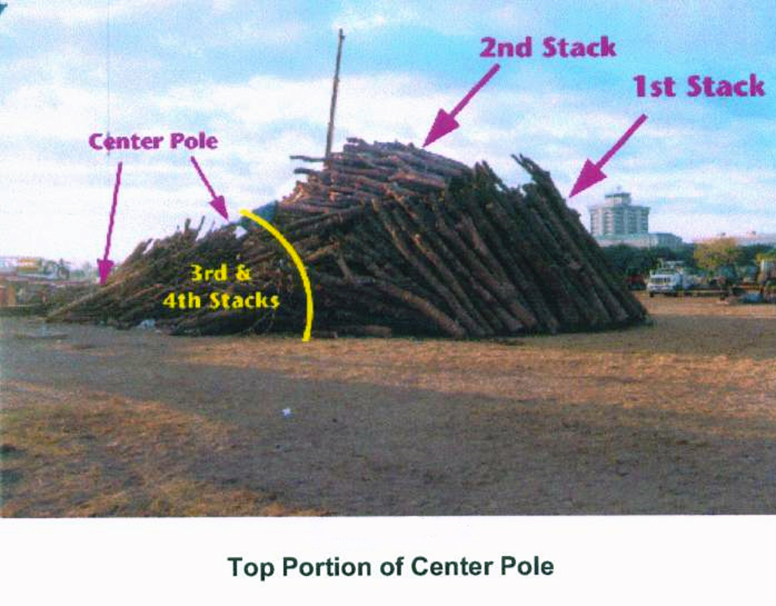

Height turned out to be another interesting aspect. Between 1910 and the 1950s, the tallest bonfire was 47 feet and all bonfires were in a teepee shape. Beginning in the late 80’s and really progressing in 1990’s the “wedding cake” designed unfolded. With the advent of the oak logs, large openings resulted. The practice of turning the logs upside down and inserting into the openings/gaps below became prevalent around 1993.

Interestingly, in 1994 the bonfire partially collapsed. When overlaid with the 1999 collapse, it was almost identical. Rather than performing a thorough investigation in 1994, it was determined that the rains and soft soil caused the gradual and final partial collapse. The difference between the two collapses was 1994’s occurred at 2:00 pm in the afternoon while 1999 the collapse occurred around 2:00 am. Students and corps only worked on the bonfire from 6:00 pm to 6:00 am.

Investigators interviewed hundreds of students involved with the project and found there was never a true design of the bonfire and it was never built the same way twice. Ultimately, two primary factors responsible for the collapse. First, excessive internal stresses driven primarily by aggressive wedging of second stack logs into the first stack. Second, inadequate containment strength. The wiring used to tie the logs together provided insufficient binding strength. Steel cables, which in recent years had been wrapped around the first stack, were not used in 1999, further reducing containment strength.

Following the 1999 disaster, Texas A&M University officially retired the bonfire tradition and built the Bonfire Memorial in its place, dedicated in 2004. The Aggie Bonfire continues off-campus, starting in 2002 under a non-profit organization called Student Bonfire(1). New bonfire projects are now overseen by construction professionals and engineers, mostly former Aggies, and are topped with a flag bearing the names of the 12 students who died in the 1999 collapse. (2)

My thoughts:

This was a very emotional assignment as we were dealing not only with loss of human life, but of young college students. As part of the bonfire tradition, each year a prior graduate is asked to be at the top of the bonfire to turn over the building of the bonfire from the Brown Pots (Juniors) to Red Pots (Seniors). Unfortunately, in 1999, that graduate was the son of one of the UT doctorial committee members and acquaintance of mine, Dr. John Breen. When I gave a presentation later on the bonfire collapse at the University of Texas, I was asked by Dr. Breen to meet with him individually and discuss the presentation, as he just could not attend the presentation.

Sources:

- Aggie Bonfire, Wikipedia- https://en.wikipedia.org/wiki/Aggie_Bonfire

- “The Burning Desire of Texas A&M”, by Scott Eden, ESPN. ESPN.com, http://www.espn.com/espn/feature/story/_/id/11937545/texas-bonfire-burns-fifteen-years-collapse-kills-12-students

About the author:

Jim D. Wiethorn, Ph.D., P.E., Principal Engineer, is the head of Haag’s Crane Group based in Sugar Land, TX. Haag’s crane group investigates all aspects of the crane and rigging related accidents. Jim Wiethorn is a third-generation general contractor and has owned, operated, and used cranes throughout his professional career. In order to better understand and become more involved in the crane industry, Jim became a member of the National Commission for the Certification of Crane Operators (NCCCO) on the Tower Crane Committee and Rigging Task Force Committee. Jim also serves as a member of the American Society of Mechanical Engineers (ASME) B30 Main Committee, Safety Standard for Cableways, Cranes, Derricks, Hoists, Hooks, Jacks and Slings, as well as the ASME B30.3-Tower Cranes and ASME B30.29-Self-Erect Tower Cranes sub-committees. Jim has testified in over 200 depositions and 100 trials during his career. Wiethorn serves on the Board of Advocates of the Engineering and Computer Science School, Baylor University and the Engineering Advisory Board of the Cockrell School of Engineering, University of Texas at Austin.

Any opinions expressed herein are those of the author(s) and do not necessarily reflect those of Haag Engineering Co., Haag Construction Consulting, Haag Education, or parent company, Haag Global, Inc.