August 2023

NHTSA CAMPAIGN NUMBER: 23V575000

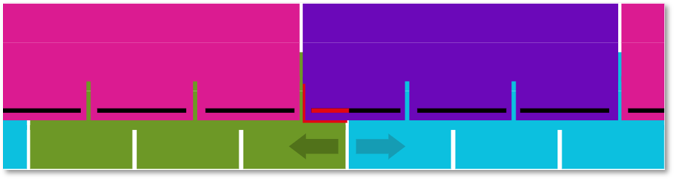

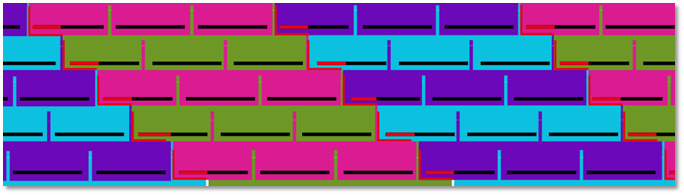

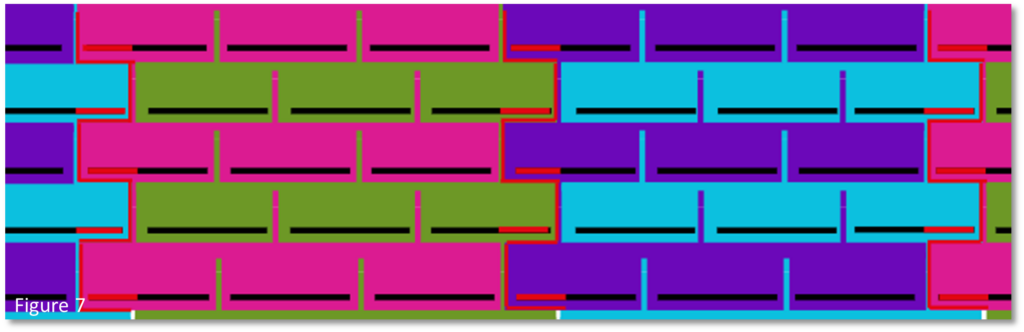

30-Amp Shore Power Inlet Failure May Cause FireA D-ring that cracks or fails may allow wires to loosen, causing electrical arcing and increasing the risk of a fire.

NHTSA Campaign Number: 23V575000

Manufacturer Forest River, Inc.

Components ELECTRICAL SYSTEM

Potential Number of Units Affected 16

Summary

Forest River, Inc. (Forest River) is recalling certain 2024 Coachmen Beyond, Galleria, and Nova motorhomes, equipped with certain SmartPlug 30-Amp Shore Power Inlets. The manganese bronze D-rings may crack or fail when over-tightened.

Remedy

Dealers will install a new smart plug, free of charge. Owner notification letters were mailed August 16, 2023. Owners may contact Forest River customer service at 574-825-6319. Forest River’s number for this recall is 225-1669.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153) or go to www.safercar.gov.