Effects of Hail-Caused Dents on the R-value of Roof Insulation

The subject property was a distribution center in Texas with several large buildings covered with single-ply, thermoplastic polyolefin (TPO) membrane roofs installed over various substrates. Concerns were raised regarding hail-caused damage to the roofs and the effects hail-caused dents had on the thermal properties of the insulation. A Haag engineer performed the roof inspection and provided samples of the TPO membrane and insulation substrates to our laboratory to determine if hail-caused dents in the substrates had reduced the insulation R-value.

Four substrate samples were provided to our laboratory. Substrates included various thicknesses of polyisocyanurate insulation (polyiso), including two topped with gypsum coverboard. Table 1 summarizes substrate configurations.

Table 1: Sample Descriptions | |

Sample | Substrate |

1 | 1/2-inch gypsum coverboard over 3-1/2 inches of polyiso |

2 | 4 inches of polyiso |

3 | 2 inches of polyiso |

4 | 1/2-inch gypsum coverboard over 2-1/2 inches of polyiso |

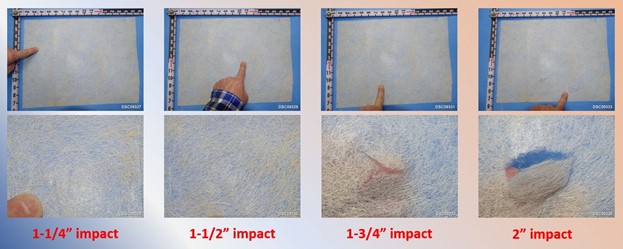

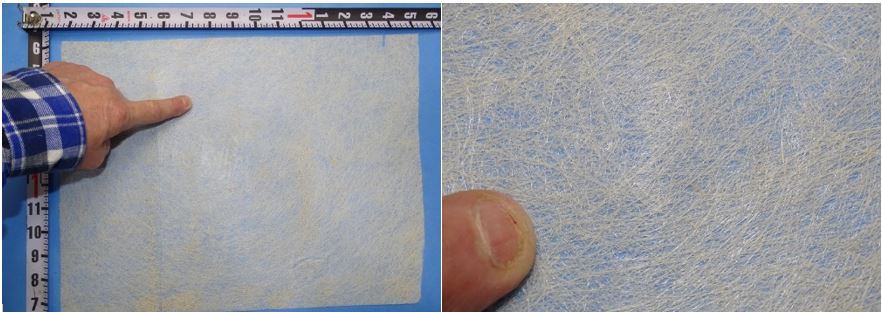

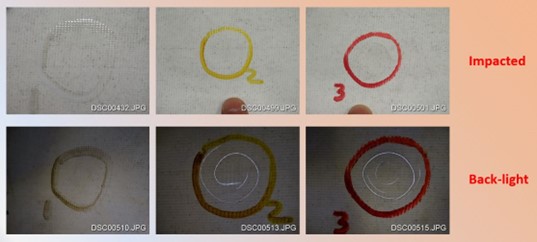

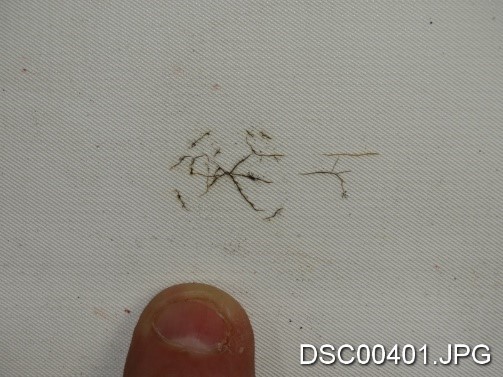

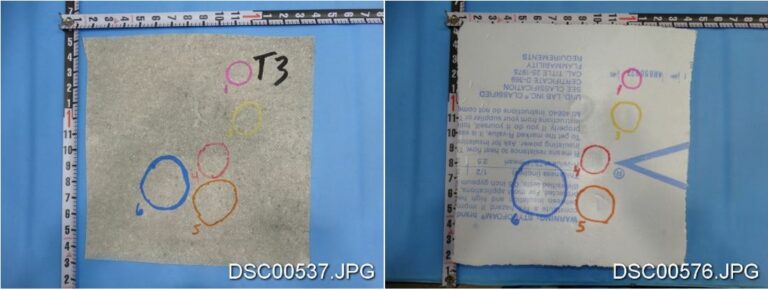

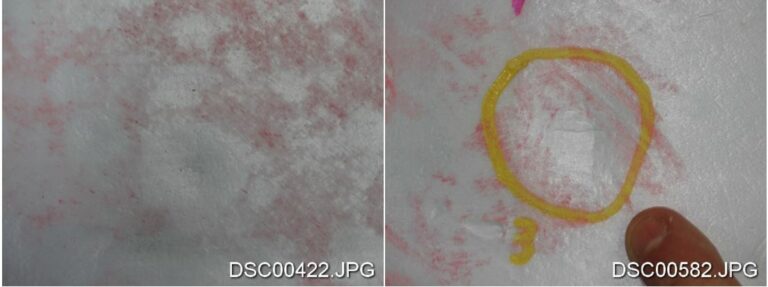

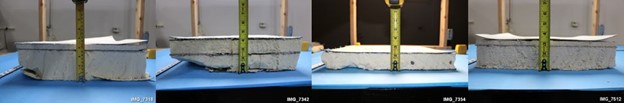

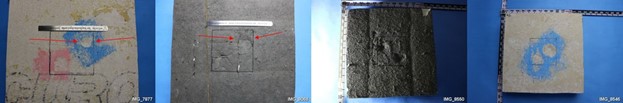

Each substrate sample contained a hail-caused dent centered on the sample. Laboratory personnel prepared each sample for R-value testing by conditioning in a laboratory oven to remove any residual moisture (absorbed humidity) and trimmed the samples to fit inside our heat flow meter (HFM), which is used to perform ASTM C518 – Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Apparatus. Samples were then tested to determine their baseline R-values.

Test parameters were chosen such that the bottom of each sample was in contact with a cold plate set at 75 degrees Fahrenheit and the top surface of each sample was in contact with a hot plate set at 145 degrees Fahrenheit. These temperatures were selected in accordance with ASTM C1058 – Standard Practice for Selecting Temperatures for Evaluating and Reporting Thermal Properties of Thermal Insulation because they represent in service temperatures of a roof on a hot summer day (upper plate) and a conditioned space below the roof (lower plate).

After baseline R-values were measured, a single dent was added to each sample that was similar in size and depth as the existing hail-caused dents and the R-values were remeasured. Test results are summarized in Table 2. The measured R-values after denting were then compared to the baseline R-values. Review of the measured R-values revealed the differences in R-value in the dented configurations versus baseline values for each sample fell within the accuracy of the HFM, which is +/- 2%.

Table 2: Measured R-values | |||||||

Sample | R-value (Baseline) | R-value (After Denting) | Difference (percent) | ||||

1 | 12.62 |

| 12.48 |

| -1.1 | ||

2 | 16.05 |

| 16.05 |

| 0.0 | ||

3 | 8.76 |

| 8.75 |

| -0.1 | ||

4 | 11.07 |

| 11.05 |

| -0.2 | ||

An additional consideration, is the R-value measurements taken within the HFM are made within a 4-inch by 4-inch region (metered region) in the center of the HFM. Also, one dent in the insulation is the smallest number of dents that can be measured for comparison. One square of roofing (100 square feet) is 900 times larger than the metered region within the HFM. For this reason, the differences in R-values listed in Table 2 represent a hail dent frequency of 900 hail-caused dents per square. The engineer that performed the roof inspection reported between two and seven hail-caused dents per square in the various substrates. Consequently, the hail-caused dents had no measurable effect on the R-value of the insulation.