Can 36-inch laminated asphalt shingles be repaired with metric-sized laminated asphalt shingles?

By Steven R. Smith, P.E., Director of Research & Testing, Forensic Engineer

Laminated shingles today are manufactured in “metric” sizes, which nominally measure one meter in length and about 1/3 meter in width. Long ago, several roofing manufacturers made laminated shingles the same size as their three-tab varieties, which were, and continue to measure 36 inches in length and 12 inches in width. Many of the older, 36-inch-long shingles are still in service today, but can a reliable roof repair be made to an old roof using larger, modern day laminated shingles?

This has become a common question in today’s roofing industry because of possible issues regarding mismatched nailing patterns, misalignments, aesthetic issues, exposed nails and unsightly overlaps. These questions have further raised concerns that making repairs with larger shingles could cause roof leaks or diminish the wind resistance of the roof.

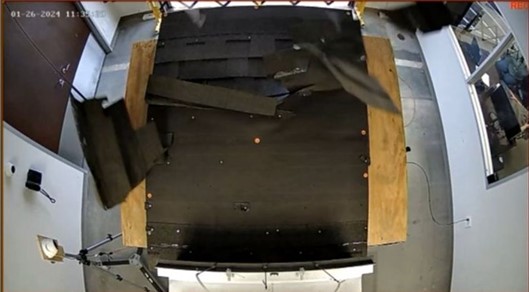

Haag Research & Testing, a division of Haag Global, delved into this topic by purchasing bundles of discontinued, 36-inch-long shingles and tested repair methods for their viability. We evaluated the process of trimming a larger metric shingle down to size for use in making repairs to the smaller, 36-inch-long shingles. Our procedures evaluated nailing patterns, overlaps, alignments, and even the wind resistance of repairs using our state of the art wind generator.

Our procedures, technical considerations, test methods, and results are presented in a new technical publication titled “Repairing an Existing 36-inch Laminated Asphalt Shingle with Metric-Sized Laminated Asphalt Shingles”. The paper discusses the technical considerations regarding fastener placement, the use of shingle adhesive, effects of ambient temperatures during roof installation, and even an unexpected consequence when old, but otherwise new shingles (still in their bundle packaging) are installed.

View Haag Research & Testing’s study, available for purchase here.

Author

STEVE SMITH, P.E., DIRECTOR OF RESEARCH & TESTING, PRINCIPAL ENGINEER

Steven R. Smith is a Forensic Engineer with Haag Engineering Co., and the Director of Research & Testing. Mr. Smith is an experienced forensic engineer who began his career with Haag more than 24 years ago. He spent seven years working as a Senior Lab Technician while earning a Bachelor of Science in Mechanical Engineering degree from The University of Texas at Arlington. He has been involved with the lab throughout his career, and has been able to leverage his extensive and practical engineering field experience with research and testing projects.

Mr. Smith’s areas of expertise include accident reconstruction, mechanical equipment evaluations, code and standards compliance, roofing system evaluations, and fires and explosions. He is a licensed Professional Engineer in Arkansas, Minnesota, Missouri, Oklahoma, Texas, and Wisconsin. He is a member of the American Society of Mechanical Engineers (ASME), Society of Automotive Engineers (SAE), and Pi Tau Sigma National Honor Society. Prior to joining Haag, Mr. Smith was a Petty Officer Second Class in the United States Navy. He trained at the Navy Nuclear Power Training Command Center in Orlando Florida and was stationed on the USS Arkansas (CGN-41), where he maintained reactor and steam plant chemistry, performed radiological controls, and operated mechanical equipment in the propulsion plant.

Steven R. Smith is a Forensic Engineer with Haag Engineering Co., and the Director of Research & Testing. Mr. Smith is an experienced forensic engineer who began his career with Haag more than 24 years ago. He spent seven years working as a Senior Lab Technician while earning a Bachelor of Science in Mechanical Engineering degree from The University of Texas at Arlington. He has been involved with the lab throughout his career, and has been able to leverage his extensive and practical engineering field experience with research and testing projects.

Mr. Smith’s areas of expertise include accident reconstruction, mechanical equipment evaluations, code and standards compliance, roofing system evaluations, and fires and explosions. He is a licensed Professional Engineer in Arkansas, Minnesota, Missouri, Oklahoma, Texas, and Wisconsin. He is a member of the American Society of Mechanical Engineers (ASME), Society of Automotive Engineers (SAE), and Pi Tau Sigma National Honor Society. Prior to joining Haag, Mr. Smith was a Petty Officer Second Class in the United States Navy. He trained at the Navy Nuclear Power Training Command Center in Orlando Florida and was stationed on the USS Arkansas (CGN-41), where he maintained reactor and steam plant chemistry, performed radiological controls, and operated mechanical equipment in the propulsion plant.

Any opinions expressed herein are those of the author(s) and do not necessarily reflect those of Haag Technical Services, Haag Engineering Co., Haag Education, or parent company, Haag Global, Inc.