Piecing Together the Weather Puzzle – An Introduction to Forensic Meteorology

By Fred Campagna, CCM, CBM, Senior Forensic Meteorologist

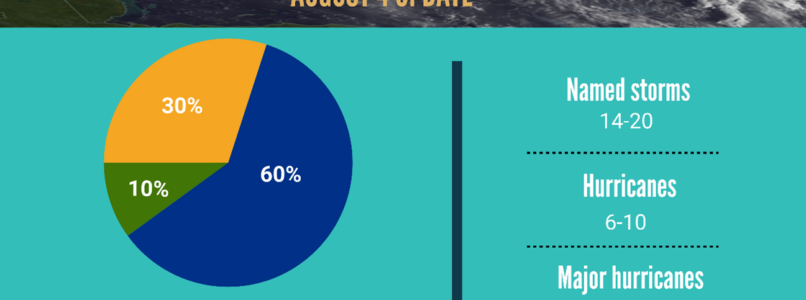

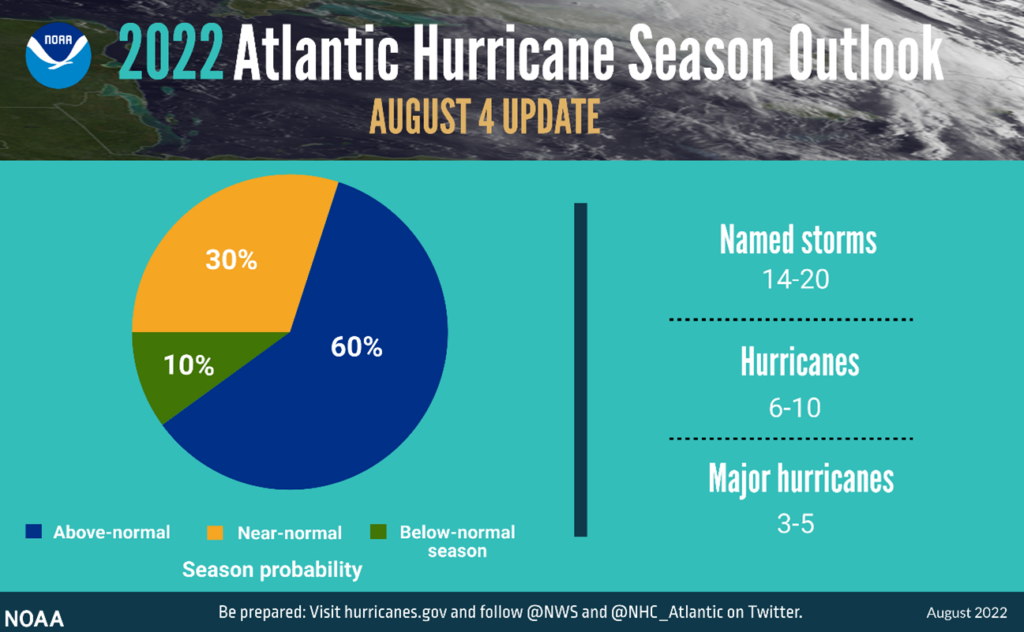

Since 1980 the United States has faced a whopping 357 weather and climate disasters where overall damages/costs exceeded $1 billion. That’s an average of 8.1 per year, and the number is increasing over time. There were 18 events in 2022 that exceeded $1 billion, and the total cost of those events was a staggering $175.2 billion. As of early June 2023, there have already been nine weather/climate disaster events exceeding $1 billion in damages/costs.

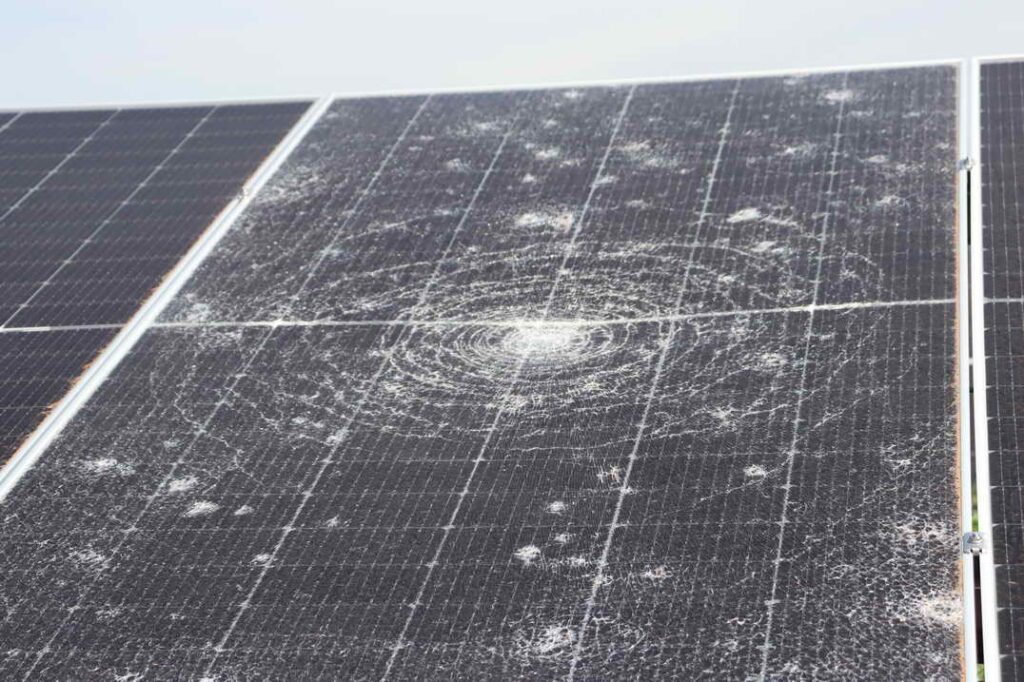

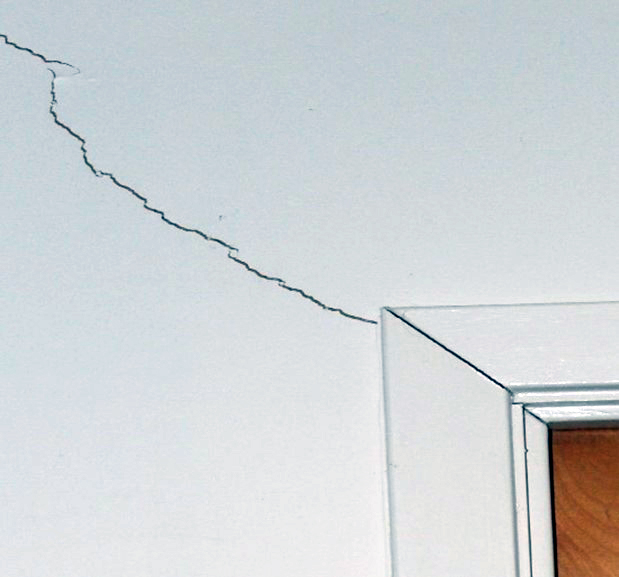

With an ever-increasing number of major weather events seemingly exacerbated by climate change, the ability to accurately recreate what the weather conditions were at any given place and time is paramount given the huge number of insurance claims and litigation that ultimately stem from these events. That’s where the science of forensic meteorology plays a critical role in helping show the ground truth at a singular point during a weather event.

Sifting Through a Vast Archive of Data

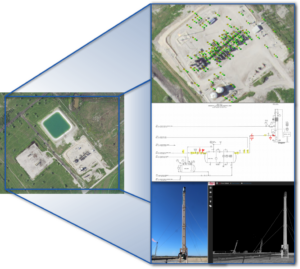

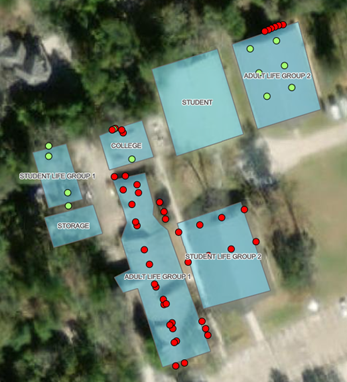

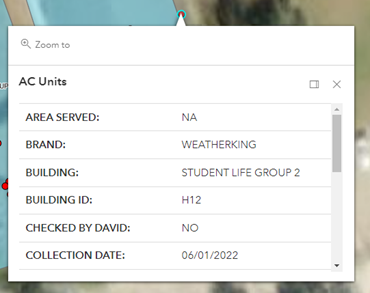

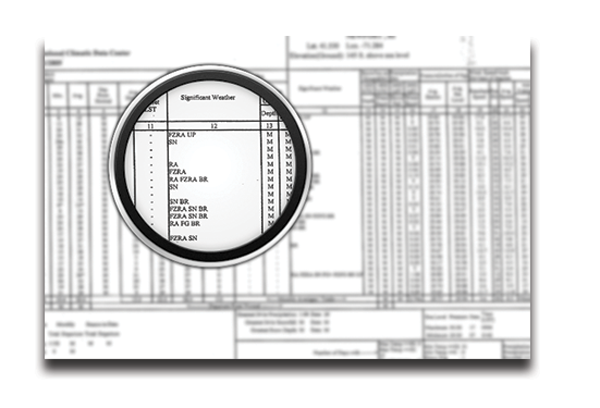

Whether it’s a $1 billion dollar disaster or a localized thunderstorm that causes damage to a few structures, there are a bevy of tools at the disposal of a forensic meteorologist to begin piecing together what the weather was like when the storm struck. The United States has over 900 land-based Automated Surface Observing Systems (ASOS) sites operated jointly by the National Weather Service (NWS), Federal Aviation Administration (FAA), and Department of Defense (DOD). In addition, there are approximately 650 similarly reliable Automated Weather Observing System sites operated by state or local governments and other non-federal entities. While 1500+ stations may seem like enough to blanket our country, there can be sizeable distances between these stations, and the weather that happens at an ASOS/AWOS station may not reflect what the weather was just a mile or two away. Thankfully, those stations are just one tool in the toolbox of a forensic meteorologist.

The National Centers for Environmental Information (NCEI) keeps a record of quality-controlled severe weather data from across the country. The Storm Events Database contains reports from NWS surface instruments; eyewitness reports by trained storm spotters or emergency management officials; media and social media reports; and occasionally, the reports of observations teams dispatched by the NWS. This searchable database can provide a few more clues to a forensic meteorologist, and the picture may come into slightly better focus, but it’s still not sharp enough.

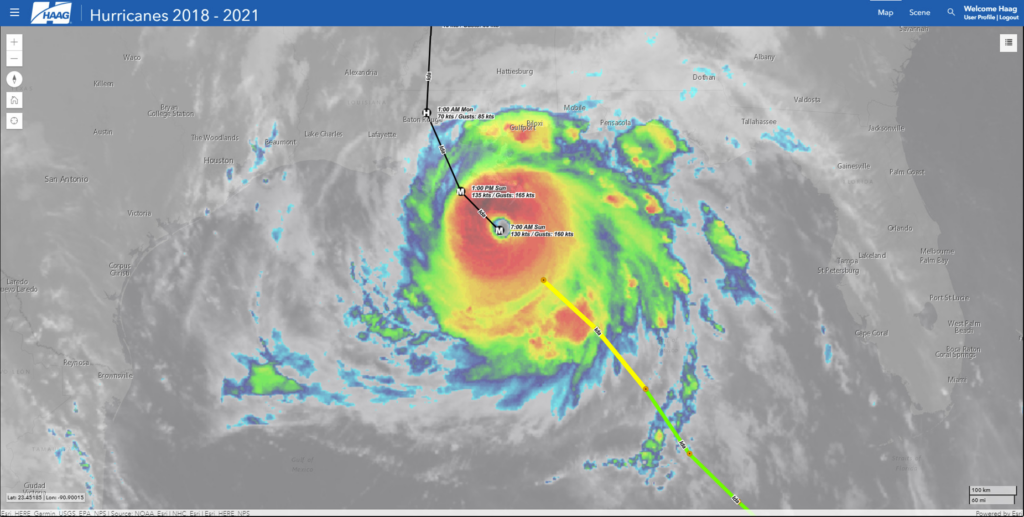

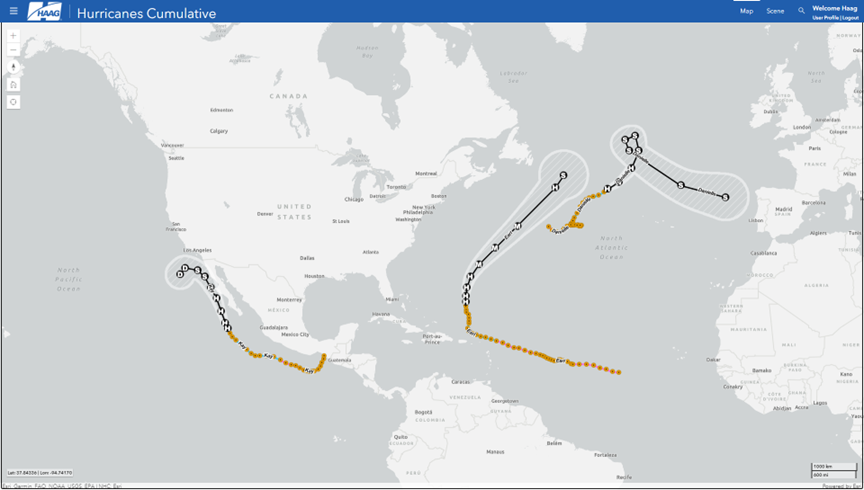

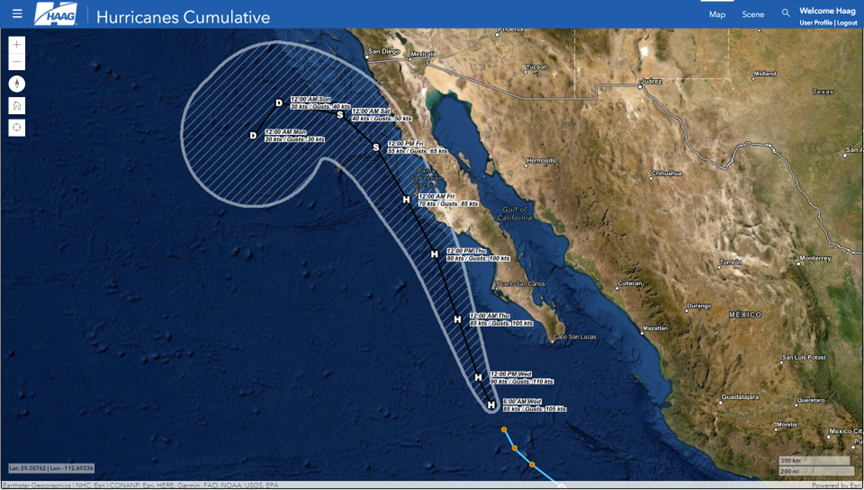

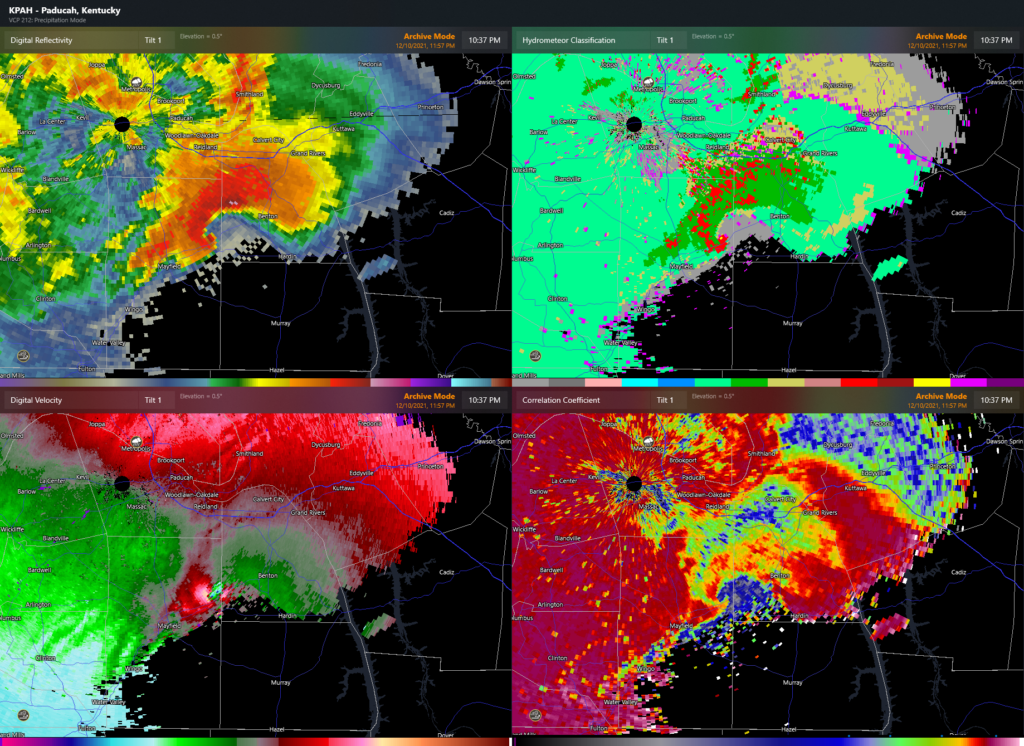

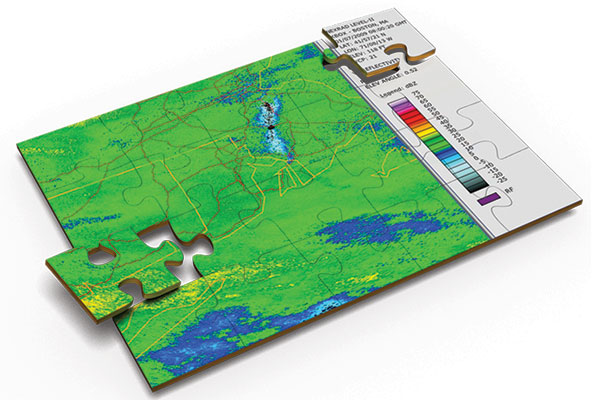

The United States also contains a dense network of weather radar scanning the skies every 1-5 minutes to help determine precipitation rate, precipitation type, wind speed/direction, and more. There are more than 200 combined Next Generation Weather Radar (NEXRAD) and Terminal Doppler Weather Radars (TDWR) to help fill in the gaps between in-situ observations from ASOS/AWOS stations and the reports in the Storm Events Database. A forensic meteorologist uses data from these advanced radar systems to drill down even farther into exactly what was happening at any street corner in the country at a specific minute of any day for the past decade or more.

While land-based observations, the Storm Events Database, and weather radar are three important sources of weather data, they are not the only three that can be useful for a skilled forensic meteorologist. A thorough analysis may also include retrieving data from other sources including local storm reports through volunteer organizations (CoCoRaHS); news reports; archived National Weather Service forecasts, warnings, and advisories; archived computer model data; and other climate monitoring products available from NCEI for snow, ice, flood, drought and more.

Certified Consulting Meteorologists – A Standard of Excellence

The puzzle pieces are many, and when it comes to putting them all together in a scientifically sound and succinct report, a Certified Consulting Meteorologist (CCM) is the best person for the job. The American Meteorological Society has awarded fewer than 800 CCM designations since 1957, and only about 250 are considered active in the field. A CCM candidate needs not only the requisite education and at least 5 years’ professional experience, but also must complete a rigorous application and testing process requiring multiple letters of reference, a written exam with 90 days to complete, a consulting essay, and finally an oral examination in front of the CCM board. Professional development activities are necessary to maintain an active CCM distinction. Haag Global, Inc. is proud to have three active Certified Consulting Meteorologists on our team, so you can rest assured that your assignment will be handled with the utmost professionalism, expertise, and highest ethical standards.

Author

Fred Campagna, CCM, CBM, Senior Forensic Meteorologist

Fred Campagna is a Senior Forensic Meteorologist with Haag Global. He is a veteran on-air meteorologist with 25 years’ experience in Atlanta, Boston, and throughout the Northeast. Fred has worked as forensic and consulting meteorologist for 11 years. He is President and Chief Meteorologist at Right Weather LLC, where he provides private forecasts for weather-dependent businesses and municipalities, consulting meteorology for civil and insurance-related legal cases, and courtroom and deposition testimony.

Fred’s certifications include American Meteorological Society’s Certified Consulting Meteorologist designation, September 2020, and American Meteorological Society’s Certified Broadcast Meteorologist designation in March 2006. He was awarded American Meteorological Society’s Television Seal of Approval, among numerous other honors and awards. He holds a Bachelor of Science degree (cum laude) in Meteorology from Plymouth State University, Plymouth, New Hampshire, where he also served as Vice President, Plymouth State College Chapter of American Meteorological Society. He also earned a Bachelor of Arts degree in Economics (Business Emphasis) from the University of Colorado, Boulder. He is a member of the American Meteorological Society and the Association of Certified Meteorologists (Consulting Member).

Any opinions expressed herein are those of the author(s) and do not necessarily reflect those of Haag Technical Services, Haag Engineering Co., Haag Education, or parent company, Haag Global, Inc.