VALUABLE CLUES: WHAT TO LOOK FOR DURING COMMERCIAL ROOF INSPECTIONS

by Ken Gilvary, M.S., P.E., Haag Principal Engineer, 01/2016

Commercial roofing is one of the most demanding areas for expertise in the insurance industry today, as there are millions of commercial structures and hundreds of different roofing systems and variations in application. Further, the history of a building’s roof may have a significant influence on its performance. There may be multiple layers of roofing on a single building which include different materials and installation. Turning back the layers of roofing can reveal historic clues to help us in our evaluations, similar to turning the pages of a good mystery novel. Use the following tips to aid you in resolving roofing mysteries and reaching accurate conclusions.

The three most common types of low-slope commercial roofing systems are built-up roofing, modified bitumen roofing, and single-ply roofing. Built-up roofing comprises multiple layers of felt sandwiched together with molten asphalt, which are typically covered with a protective coating, gravel ballast, or a roll-roofing cap-sheet. These built-up systems offer redundancy due to their multiple layers of reinforcements. Modified bitumen roofing systems normally comprise a felt base sheet covered with one or two plies of modified bitumen membrane. The modified bitumen membrane comprises reinforcement coated with asphalt and mixed with a plastic or rubber to make the bitumen substantially tougher and resistant to tearing. The modified bitumen also needs to be covered with a protective coating such as aluminum-rich paint or granules to protect it from sun exposure. Single-ply roof systems comprise a variety of plastics and rubbers, including ethylene propylene diene monomer (EPDM), thermoplastic olefin/polyolefin (TPO), and polyvinyl chloride (PVC). These systems are single-layer applications of roofing sheets that are bonded along their seams with heat or adhesive. They rely directly on the strength of these seam bonds to keep water from infiltrating the building. Single-ply systems are designed for direct exposure to sunlight. When evaluating a roof system, it is important to determine the constituents and attachment of the system, as this information can provide clues as to how the roofing will respond to storm events such as wind and/or hail.

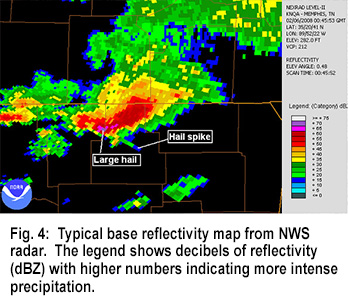

With respect to hail, we should consider that hail storms typically have a predominant fall direction. This direction can be determined by the examination of building features both on and off the roof. Hailstone impacts can leave distinct spatter marks on oxidized surfaces such as electric junction boxes, and they often leave permanent evidence of impacts as dents in metals (such as air-conditioner cooling fins, roof vents, and flashing). Roofing surfaces exposed to the predominant direction of hail-fall will experience the most severe impact, and these areas should be the first to exhibit damage, if any occurs. Likewise, if damage occurs, it is expected to be more frequent and more severe on surfaces facing the predominant hail-fall direction.

It should also be noted that roofing systems installed over softer substrates (such as foam insulation boards) are more susceptible to hail strikes than those installed over stiffer substrates (such as plywood, concrete, or gypsum cover boards). This is due to the deflection that can occur in these substances. Further, areas of ponded water can accelerate the deterioration of roofing membranes and can make these areas more susceptible to impact.

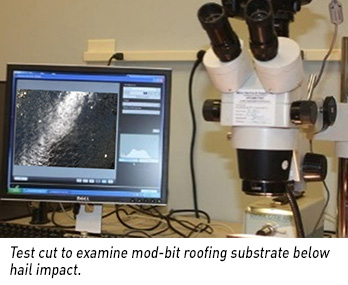

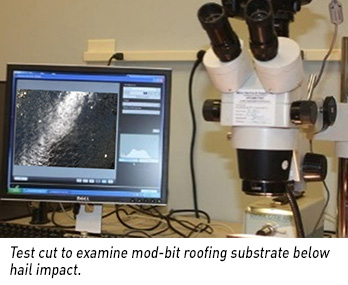

Evaluation of large hail strikes against built-up and modified bitumen roof systems often requires the removal of roofing cores, which are transported to the lab for further examination. Removal of roofing cores also permits an opportunity to determine the roof system cross-section, the membrane thickness, and to check for moisture below the roof membrane. In these instances, we regularly examine the sample under magnification, and then remove the bitumen from the core with solvent to examine the reinforcing for strain and tears characteristic of impacts. Once the roofing has been cut, you can use a tool like the Haag Panel and Membrane Gauge™ to measure and document the thickness of the membrane for your file Hail damage to single-ply roofing systems typically is discernible in the field; however, it may be helpful to remove cores from the roofing and examine areas of interest with a microscope and/or high intensity backlighting to identify fractures caused by hailstone impacts (particularly with TPO products).

With respect to windstorm evaluations, we need to recognize that a building has widely varying force levels on its roof surfaces. It is reasonable to expect the most severe wind damage to occur at the windward corners and edges of the roof where wind forces are the strongest. It is for this reason that building codes require more uplift resistance capacity for roofing in these areas. In fact, it is not uncommon for roof fastener patterns on shoreline structures and tall buildings to

require 50 percent more fasteners along the edges and 100 percent more fasteners in roofing corners than in the field of the roof. If wind forces have reached levels strong enough to damage the common commercial roofing systems, there typically is some combination of lifted, torn, and/or peeled roofing concentrated where wind forces are the strongest (ie. at the windward edges and corners of the roof). Additionally, we should examine the roof system at roof penetrations to look for wrinkles and tears or any other evidence of membrane displacement. If we find that roofing failure has occurred at wind speeds less than expected, we should examine and document the roof system attachment within those areas. Often premature failure occurs due to inadequate fasteners, inadequate adhesion, or some combination of the two. Situations such as these may be significant subrogation opportunities. In these instances, it is particularly important to turn back all of the roofing layers to properly evaluate the roof and support your conclusions. The layers of roofing, their attachments, and their performance tell the story; all we have to do is know how to read it.

Kenneth R. Gilvary is a licensed Professional Engineer in 16 states. He was employed by Haag Engineering Co. from 2003-2017. He has extensive experience with design, construction administration, and evaluation of large-scale projects involving multiple buildings. He currently sits on the Board of Directors of the Windstorm Insurance Network (WIND), Inc., and the Property Loss Research Bureau (PLRB) planning committee. He is a member of the ASTM E-06 Performance of Buildings Committee and is a developer. He was an instructor for the Haag Certified Inspector (HCI) programs. Ken also is an All-Lines Insurance General Adjuster licensed in Florida with experience in adjusting large commercial losses.

By Carlos Lopez, PhD, PE, Haag Associate Engineer

By Carlos Lopez, PhD, PE, Haag Associate Engineer

Kevin Kianka, P.E., Director of Haag BIM/Modeling Program, 07/2015

Kevin Kianka, P.E., Director of Haag BIM/Modeling Program, 07/2015