Roofing Sample Guidelines for Forensic Hail Damage Evaluations

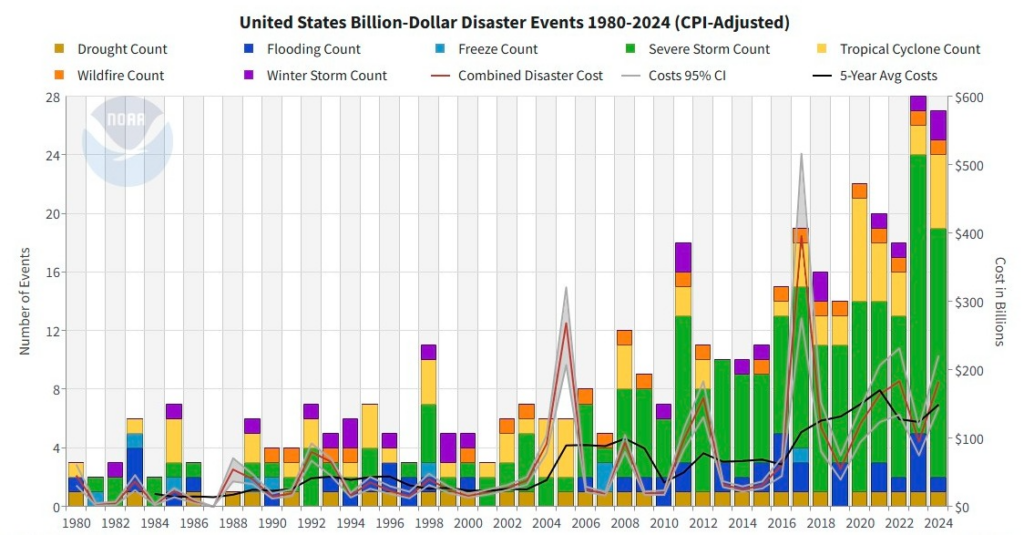

Replacing a commercial roof can cost many thousands or even millions of dollars. That is why accurate analysis of a roof is essential. Well installed and properly maintained roofs can last for decades; however, a significant weather event can damage the roof investment, and often result in conflicts between building owners, insurance carriers, roofing contractors, public adjusting firms, and yes, even attorneys. Laboratory analysis of roofing samples is unlikely to prevent such conflicts, but accurate information can help roof consultants develop well-informed opinions and play a crucial role in settling such conflicts.

The importance of laboratory testing

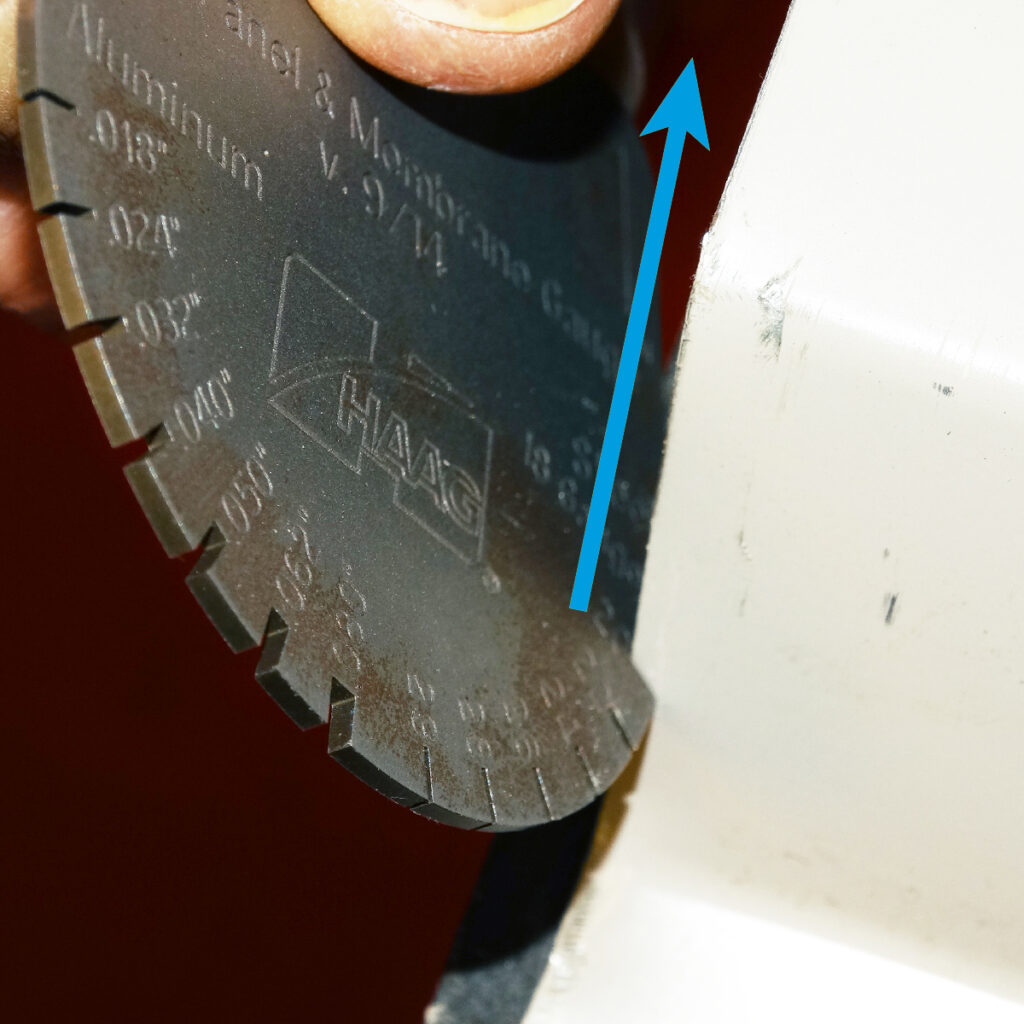

For decades, laboratory testing of roofing samples has played a key role in better understanding the cause of damage, the extent of damage, the date of damage, and even repairability of roofs. Most roof consultants do not have their own laboratories to accurately test and evaluate roofing samples, and instead, opt to remove samples and send them to Haag, or other labs throughout the country. Did you know the first crucial step in laboratory roof sample analysis has nothing to do with the laboratory itself, but instead, begins with the roof consultant’s knowledge of the roof and the laboratory testing to be performed?

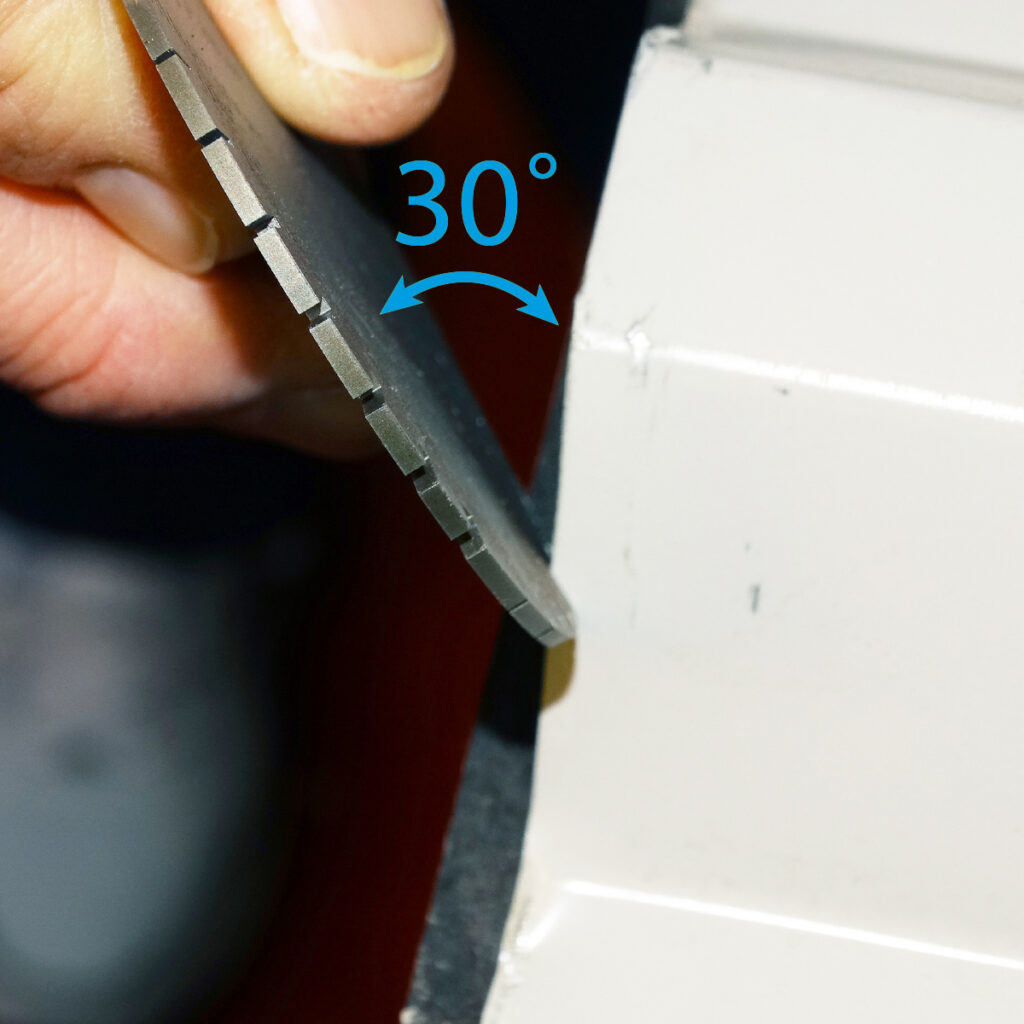

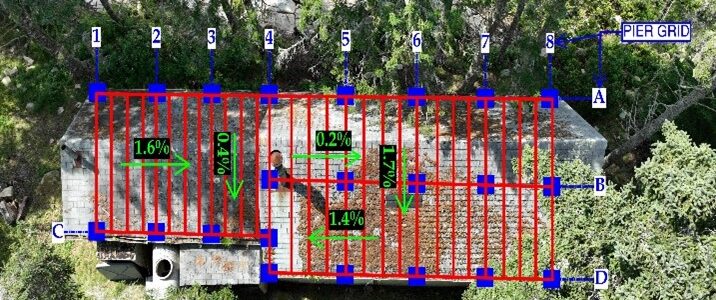

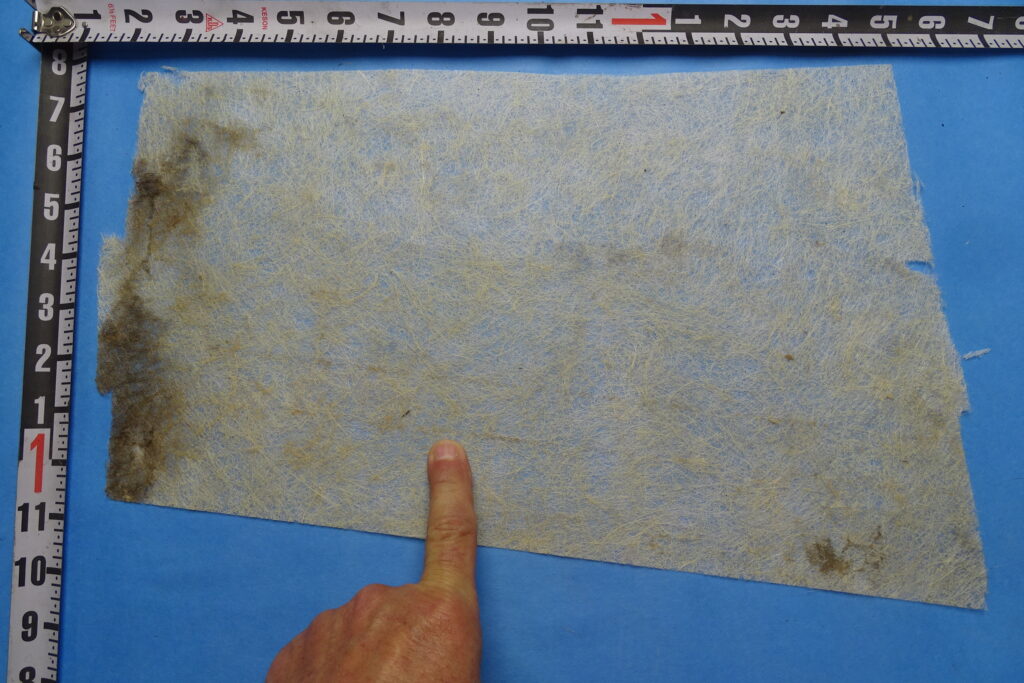

Understanding the testing to be performed can equip the roof consultant with key insights of where to take samples, what size of samples to take, and even how to position samples with respect to areas of interest (AOIs). For example, if water column testing is requested, samples should measure about 12-inches by 12-inches with the AOI centered on the sample, but if artificial hail impact testing is to be performed, a larger sample should be taken with the AOI positioned off to one side. This provides the laboratory technicians with enough room to perform the impact testing without the risk of impacting the AOI.

Lab testing of Roofing samples

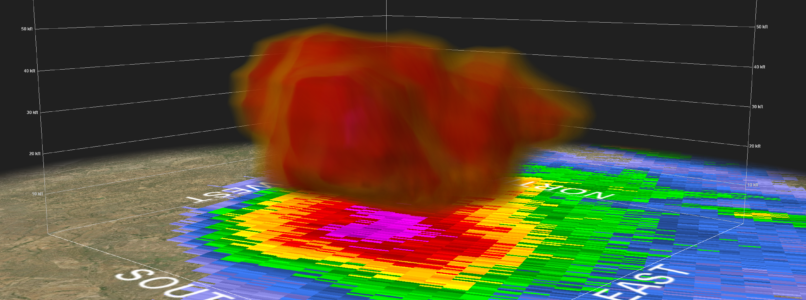

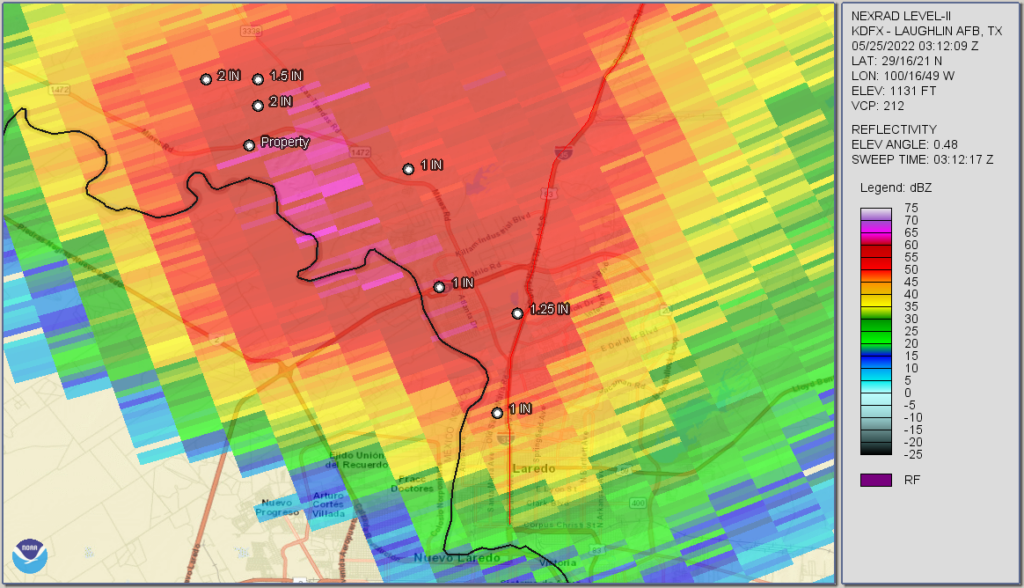

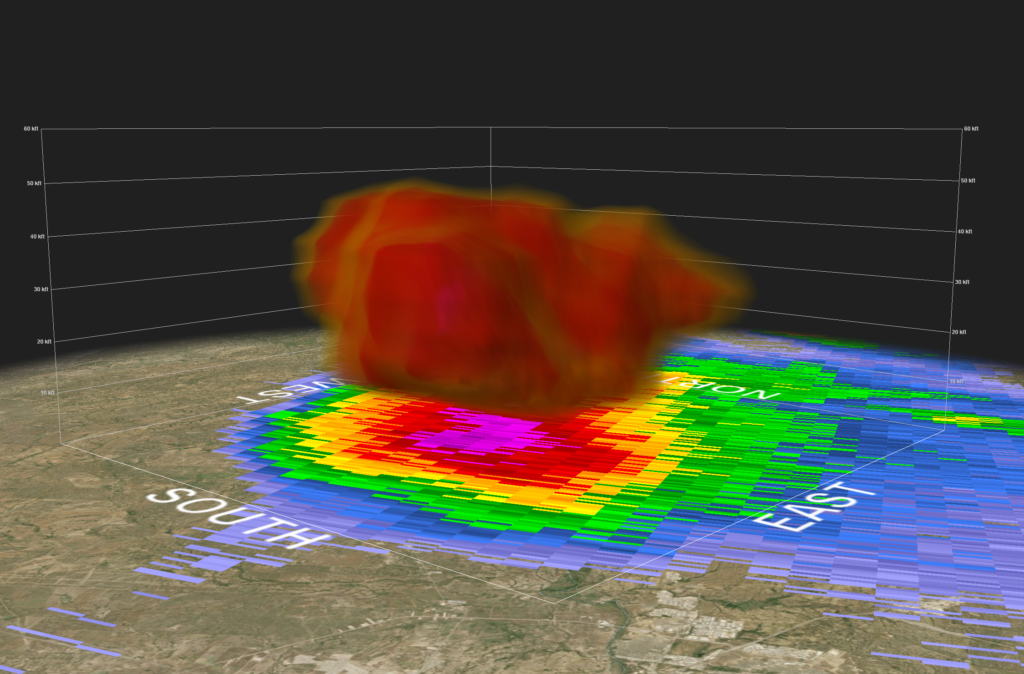

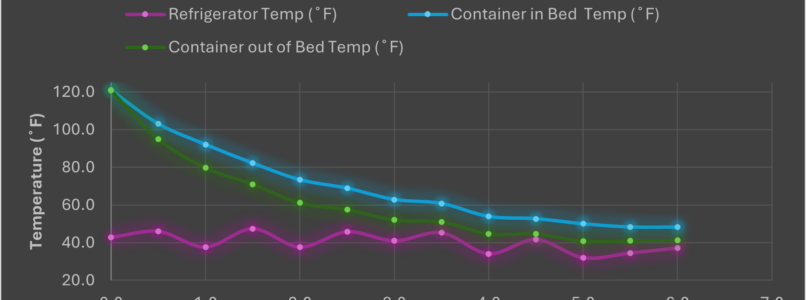

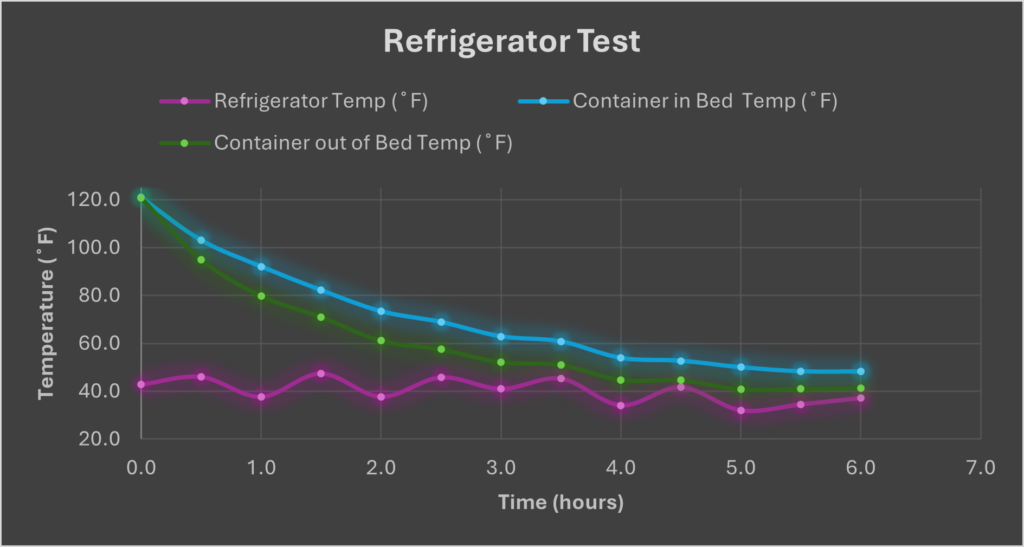

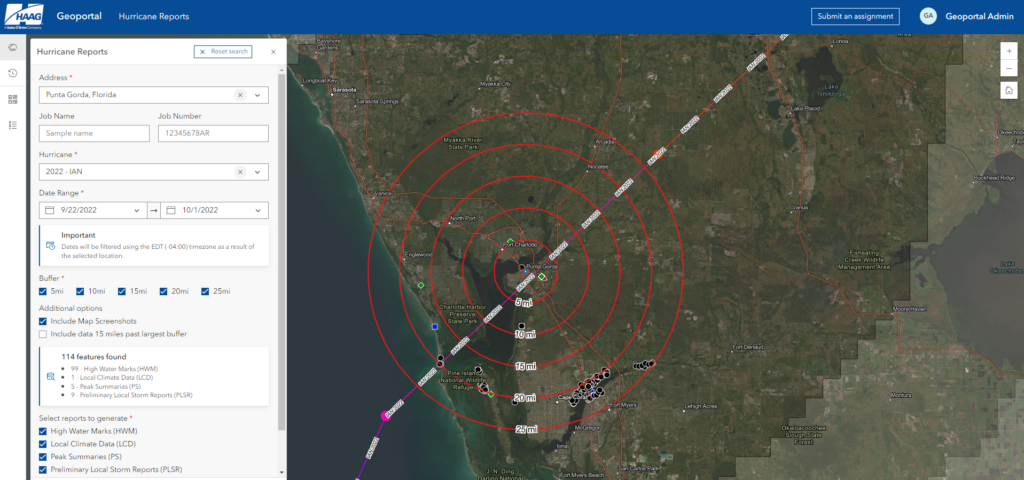

Laboratory testing of roofing samples commonly performed by Haag include simulated hail impact testing, water column testing, insulation R-value testing, desaturation of asphalt-based roofing, and analysis of single-ply roofs. Each of these tests provide information unobtainable by field inspections alone, and when used in conjunction with field inspection data and weather data, can help form a complete understanding of the roof. Testing can help determine if a sample was damaged by hail, the minimum size of hail able to damage a sample, when hail-caused damage may have occurred, if a hail impact location (or other region) is water-tight, if hail dents in the insulation below the sample adversely affected its R-value, and if a hail-caused condition was limited to the surface coating or if impact damage extended completely through the sample.

Most common laboratory tests

Haag forensic consultants, consultants from other firms, contractors, public adjusters, insurance professionals, building owners, attorneys, and manufacturers frequently request the following tests from Haag’s laboratory–

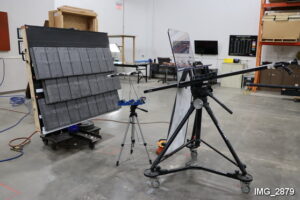

- Simulated hail impact testing, based on ANSI/FM 4473 – Test Standard for Impact Resistance Testing of Rigid Roofing Materials by Impacting with Freezer Ice Balls

- Desaturation analysis, based on ASTM D3746 – Standard Test Method for Impact Resistance of Bituminous Roofing Systems

- Single-ply analysis, a series of inspection techniques, using tactile examination, back-lighting, and microscopy.

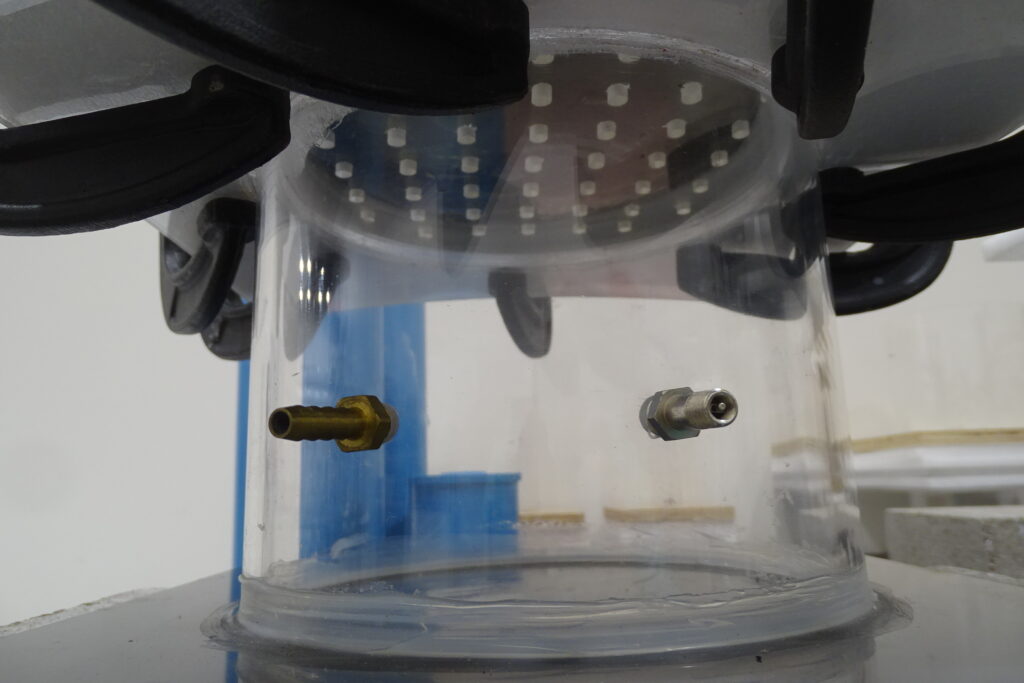

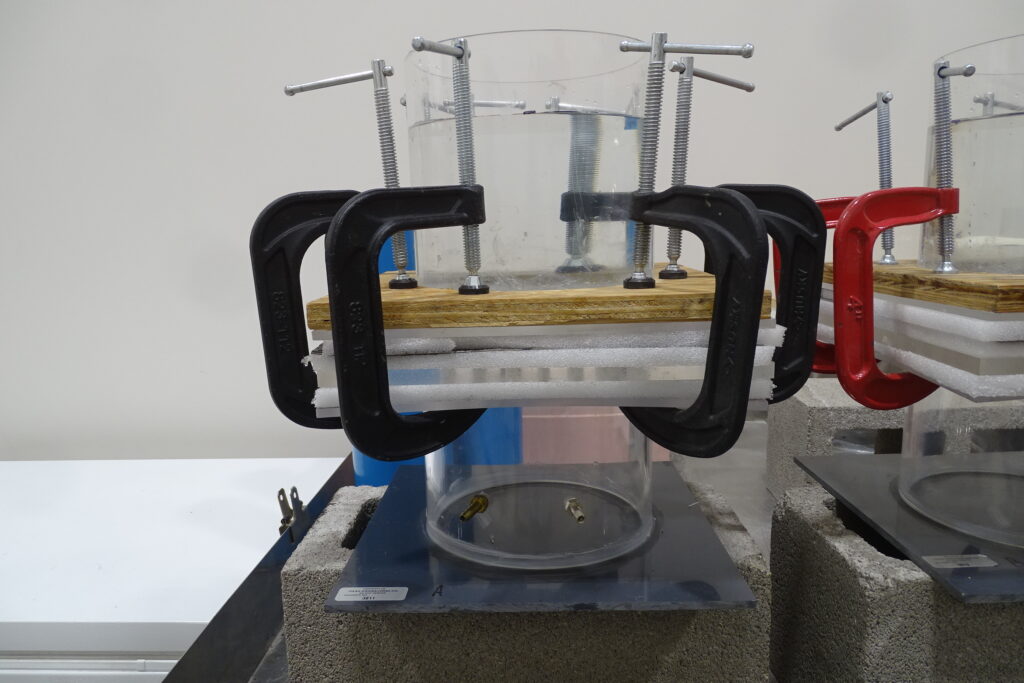

- Water column testing, based on ASTM D7281 – Standard Test Method for Determining Water Migration Resistance Through Roof Membranes

- R-value testing, based on ASTM C518 – Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Apparatus

Roofing Sample Guidelines for forensic hail damage evaluations

Haag Research & Testing is pleased to announce the development of a new, free publication–Roofing Sample Guidelines for Forensic Hail Damage Evaluation— intended to assist roof consultants with the selection and sizing of roofing samples for laboratory analysis. A link to this publication can be found here.

Haag Research & Testing an accredited testing laboratory through the International Accreditation Service (IAS) and is listed as Testing Laboratory 656 (TL-656) on the IAS website.

Whatever your testing needs, Haag has the resources and expertise to support your goal. To explore testing options, please contact us or call 214-614-6500.

Steven R. Smith is a Forensic Engineer and Director of Research & Testing for Haag, a Salas O’Brien Company. Mr. Smith is an experienced forensic engineer who began his career with Haag in 1998. He spent seven years working as Haag’s Senior Lab Technician while earning a Bachelor of Science in Mechanical Engineering degree from The University of Texas at Arlington. He has been involved with the lab throughout his career and has been able to leverage his extensive and practical engineering field experience with research and testing projects. Mr. Smith has authored or co-authored several Haag publications, including Repairing an Existing 36-Inch Laminated Asphalt Shingle Roof with Metric-Sized Laminated Asphalt Shingles, Effects of Hail-Caused Dents on the Thermal Performance of Insulation Under Single-Ply Roofing, Testing of Impact-Resistant Asphalt Shingles, and Hail Effects on Air-Conditioner Performance. He also contributed to other publications as a laboratory technician, including Hail Damage Threshold Sizes for Common Roofing Materials, Hail Damage to Tile Roofing, and Hail Impact Resistance of Asphalt Shingle Overlays.

Mr. Smith’s areas of expertise include roofing system evaluations, components and cladding, code and standard compliance, and mechanical equipment evaluations. He is a licensed Professional Engineer in Texas, Arkansas, Oklahoma, Missouri, Minnesota, and Wisconsin. He is a member of the American Society of Mechanical Engineers (ASME) and Pi Tau Sigma National Honor Society. Prior to joining Haag, he trained at the Navy Nuclear Power Training Command Center in Orlando, Florida and was stationed aboard the USS Arkansas (CGN-41), where he maintained reactor and steam plant chemistry, performed radiological controls, and operated mechanical equipment in the propulsion plant.