A large grain dust explosion occurred at a grain company facility. The explosion severely damaged three connected silos and injured six workers, as employees were loading rail cars when the explosion happened, and sections of the bins toppled onto the rai.

On August 13, 2014, a large grain dust explosion occurred at the Coshocton Grain Company facility in Coshocton, Ohio. The explosion severely damaged three connected silos and injured six workers. Employees were loading rail cars when the explosion happened around 4 pm, and sections of the bins toppled onto the rail cars.(1)

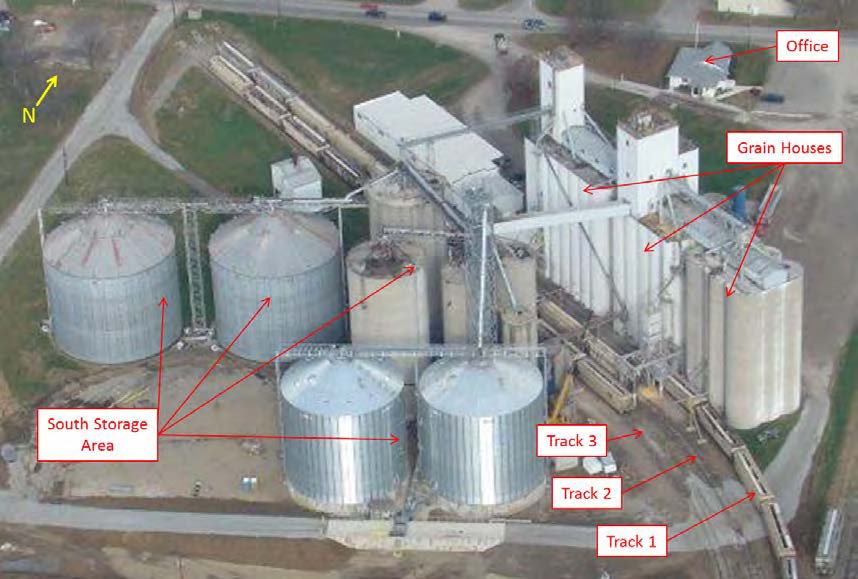

The 60-year-old Coshocton Grain facility was a 2.5-million-bushel capacity grain receiving, drying, and storage facility that included three slip-formed concrete storage houses standing more than 100 feet above grade at the bin deck. A single gallery spanned across all three houses; two of the houses had head houses. A tunnel network connected all three grain houses in the basement, and one of the houses to a truck dump building and to several silos across railroad tracks to the south. South of the railroad tracks were five additional concrete silos, four steel storage bins, and several small buildings.

Seven bucket elevators, 12 drag conveyors, 11 belt conveyors, two screw augers, and one tripper directed the flow of grain throughout the facility. In general, the equipment in the basement and ground-level directed flow of grain away from the dumps and bins, and to the boots of the elevators. Elevated equipment directed flow away from the elevator legs to the various silos, bins, dryers, and load out areas of the facility. There were also three dust collectors, a dryer, a truck scale, and a continuous flow scale.

Haag responded to determine the origin and cause of the explosion, which included coordinating with OSHA representatives and salvage efforts.

The explosion caused a large area of the middle house to blowout and the head house to fall to the ground and damage several railcars and railroad tracks. Haag’s original scope expanded to include documentation of the explosion site using 360° photography and scanning (3D laser scanning), evaluation of structural and mechanical damage caused by the explosion, and a cost estimate of the explosion-related damage.

SOURCE (1) NO GRAIN, NO GAIN: COSHOCTON GRAIN, FARMANDDAIRY.COM; HTTPS://WWW.FARMANDDAIRY.COM/TOP-STORIES/NO-GRAIN-NO-GAIN-NEARLY-A-YEAR-AFTER-A-DEVASTATING-EXPLOSION-COSHOCTON-GRAIN-IS-COMING-BACK/265567.HTML, JUNE 2015.)

Involved Experts:

- John Z. Wlascinski, Principal Engineer, Houston Branch Manager, Board Chairman