Identifying HAIL-CAUSED FRACTURES IN THERMOPLASTIC ROOFING

In most roof systems, hail-caused damage is readily identifiable, but in other systems, such as single-ply thermoplastic roofing, the damage initially can be less apparent. Imagine this scenario: a severe thunderstorm deposits hail at a commercial property. There is immediate concern that the single-ply roofing membrane had been damaged by hail. An inspection of the roof reveals spatter marks (areas of grime and oxide cleaned from surfaces struck by hailstones) and dents in metals confirming that hail had fallen at the property. The membrane is examined and the plastic single-ply is determined as not damaged. A few months later, several leaks are discovered after a heavy rain storm, prompting a follow-up roof inspection. Hail-caused fractures are discovered throughout the membrane during the second inspection. What likely happened?

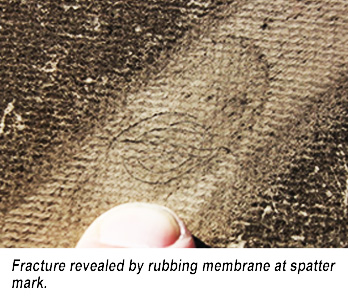

Depending on the type of roof system, hail-caused damage takes different forms. Hail-caused fractures in thermoplastic roofing range from circular to semi-circular to multiple fractures in circular patterns. Frequently, the fractures are especially “tight” after hailstone impacts. Over time, the membrane “relaxes” due to the effects of weathering, and the fractures accumulate grime making the fractures more apparent. The impact-caused fractures may not be visible to the naked eye immediately after they originate, but proper inspection techniques will aid us in identifying hail-caused damage on our first inspection visit.

First, we need to know where the thermoplastic membrane is most likely to be damaged by hail. The membrane is most sensitive to impact damage at the edges of underlying steel stress plates (washers). Depending on the roofing application, these may be found within lap seams and atop the insulation immediately below the membrane. The next areas most sensitive to damage are those not solidly supported: commonly base flashing at parapet walls and curbs. Lastly, consider membrane in the field of the roof, especially where underlying insulation boards have wide gaps or are uneven. Importantly, thermoplastic membranes become more brittle with age and therefore more impact sensitive. Sometimes brittle sections correspond to roofing areas that regularly pond water, as this prolonged contact accelerates the aging process.

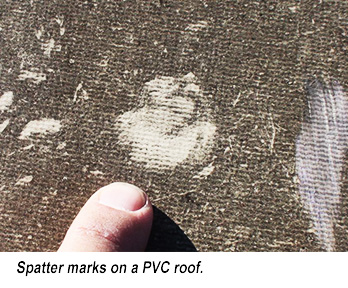

Second, we will identify locations where the membrane had been struck by hail. Normally, a thin layer of grime has accumulated on the roof. Hailstones that impact the roof clean away this surface grime, leaving a spatter mark. In general, larger or softer hail creates larger spatter marks than smaller or harder hail. Note that thermoplastic roofing typically is installed over rigid foam insulation. Impacts by large hail can dent the insulation. For this reason, even when spatter marks are not visible, we can locate impact sites by feeling dents in the insulation.

Now that we know where to look and what to look for, we can examine the roof for hail-caused fractures. Once an impact location is found (whether indicated by a spatter mark, a dent, or both), we can examine the membrane for a fracture. If a fracture is not visible, rub the impact with your fingers to force grime into the fracture (if one exists). Larger areas measuring a few square feet can similarly be rubbed by hand, providing larger areas to examine. If no fractures are observed within a test area, one could consider rubbing the entire test area by hand, providing an additional opportunity to locate hail-caused fractures.

|

|

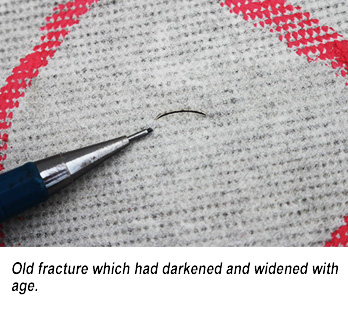

There also are instances where an inspection might reveal hail-caused fractures from a storm that occurred long ago. Old fractures have been exposed to the weather longer than more recent fractures, and hence, they tend to exhibit the following characteristics: their edges are generally more round, they are darker in color, and they are generally wider. In some cases, readily visible hail-caused fractures are observed on the roof, yet none align with spatter marks, which would clearly indicate that the fractures were not the result of the recent hailstorm.

|

The use of these techniques will aid an inspector in determining if a thermoplastic roofing membrane had been damaged by hail and whether the damage had occurred recently or if the damage was created long ago. Understanding where to look, what to look for, and how to detect hail-caused damage to thermoplastic roofing is critical in making a proper analysis.

Steve R. Smith, P.E. and Haag Senior Engineer

Steve Smith completed nuclear power training with the United States Navy in 1994. He was honorably discharged in 1998 and went to work for Haag Engineering Co. as Senior Laboratory Technician. Steve has performed hundreds of hail impact tests on a variety of products including roofing, siding, and automobiles. He graduated from the University of Texas at Arlington in 2005 with a Bachelor’s degree in Mechanical Engineering and is a member of the American Society of Mechanical Engineers, the Society of Automotive Engineers, and the National Association of Fire Investigators. Steve has inspected and assessed damage to a number of roof systems, including single-ply systems, composition shingles, cedar shake and shingles, concrete tiles, slates, and built-up roofing. See his full profile here.