Simulated Hail Impact Testing of PVC Roofing Membrane

Large school with numerous roof sections covered with a variety of single-ply roofing membrane types. One section covered with a relatively new thermoplastic polyolefin (TPO) membrane, several large sections covered with old polyisobutylene (PIB) membranes, and several sections covered with polyvinyl chloride (PVC) roofing membranes estimated at about 10 years old. School had been struck by hail on numerous occasions and the roof was examined for hail-caused damage. Some of the PVC roofing had obvious hail-caused damage and our client needed to know when the hail-caused damage had occurred.

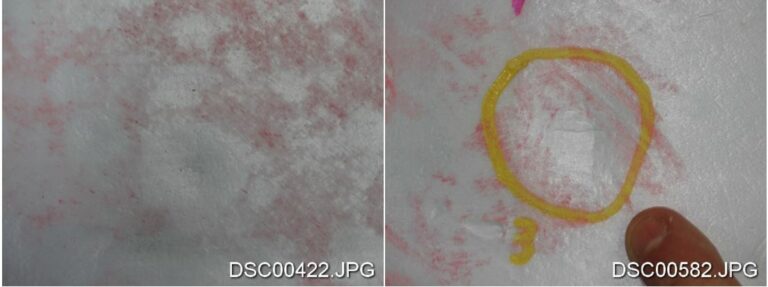

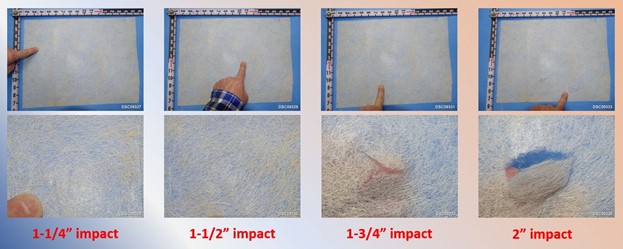

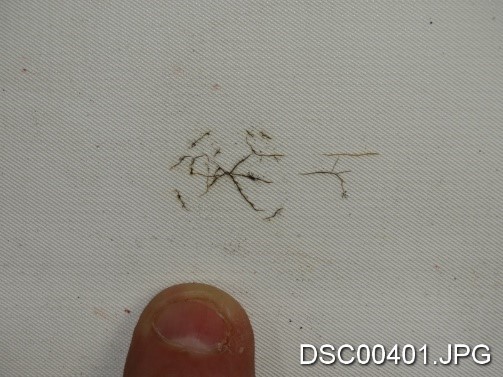

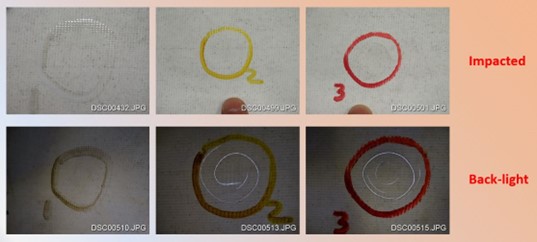

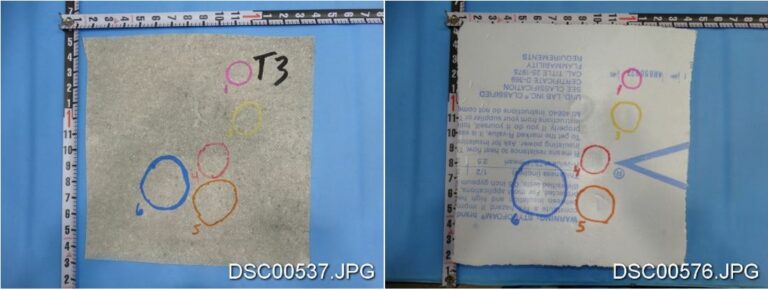

Samples of the PVC roofing were removed and tested in the HRT laboratory to determine the minimum size of hail that could damage the PVC membranes and to determine what size hail would create similar size fractures in the membrane and similar dents in the insulation. Samples and substrate taken from the roof were mounted to a panel and impact tested with various sizes of ice balls. Ice balls were frozen solid and propelled perpendicular to the test panel at free-fall velocities of similar sizes of hail to replicate worst-case impact conditions.

Based on simulated hail impact testing, the minimum size of hail that could cause similar impact damage to the PVC membranes was 1-1/4 inches in diameter. Based on a review of weather records, information gathered during our inspection, and laboratory test results, there was one specific storm that could have caused the fractures in the PVC membranes.

Hail-caused dents in the insulation were consistent in size and depth as dents resulting from simulated hailstone impacts made with ice balls measuring 1-1/4 inches in diameter, corroborating the hail-caused damage to the PVC roofing membranes were likely caused by hailstones measuring about 1-1/4 inches in diameter.