Testing Application Standard (TAS) No. 106 – Its Importance and Intended Use

In this month’s blog post, we at Haag Engineering Co. (Haag) talk about the TAS 106 (Standard procedure for field verification of bonding of mortar or adhesive set tile systems and mechanically attached rigid, discontinuous roof systems). Within the forensic engineering, roofing, and insurance industries, we are experiencing continued use of the Florida Building Code’s (FBC) TAS 106 for the determination of wind-related damage to tile roof systems. The objective of this blog post is to simplify, understand, and ultimately convey the importance and intended uses of the TAS 106.

(Click here for the PDF version of this blog post.)

What is TAS 106? How is it used? What is it used for?

In short, and per the FBC, “This Application Standard is a product application quality control test to confirm: 1) sufficient bonding by the mortar or adhesive to the tile and underlayment in a mortar or adhesive set tile system; or 2) effective mechanical attachment of components within a rigid discontinuous roof system.”

The TAS 106 is performed to confirm if the method of attachment is sufficient/effective to resist the designed wind loads of the tile roof system shortly after the completion of a roof installation in High-Velocity Hurricane Zones (HVHZ). Per the FBC Section 1512, “…upon completion of all adhesive and mortar-set tile systems, and prior to the final inspection, field verification, and static uplift test, in compliance with TAS 106 shall be required to confirm tile adhesion to the underlayment.” Further, the FBC states, “This test may be required by the building official for mechanically attached tile systems.” Although the TAS 106 can be performed on any tile roof system, field testing in accordance with the TAS 106 is only required within High-Velocity Hurricane Zones in Florida – which encompasses only Miami-Dade and Broward Counties.

Field verification, testing, and recorded data in accordance with the TAS 106 shall be performed by a Dade County Approved Testing Agency and consists in part of the following:

The inspector must test 10% of field tiles and 20% of perimeter/corner tiles for proper attachment. At least 97% of the tested tiles must be adequately attached; if not, the roof fails the test and requires remediation. Proper attachment shall be determined by a tile that remains bonded, does not break/crack, and/or does not lift more than 2 inches along the nose, when lifted with a static load of at least 35 lbs. or not less than 80% of the design load.

Can the TAS 106 be used to evaluate if a tile roof system is wind damaged?

No. Rather, the TAS 106 is a product application quality control test performed by a Dade County Approved Testing Agency to confirm the adequate attachment of tile roof systems within the HVHZ. The determination of whether a tile roof is damaged by wind forces is performed through forensic inspection methodologies that do not require the use of TAS 106. Wind damage to tile roofs typically consists of displaced or missing tiles, initiating at roof edges, corners, and peaks (susceptible areas of the roof structure exposed to higher wind uplift forces). Tile roofs also may experience indirect wind damage in the form of impacts from windborne debris or impacts from falling trees and other items that tend to accompany high-speed winds. Other factors that can contribute to the failure of tile roofs may include age, maintenance, method of attachment, and pitch of the roof slopes. (For more information and certified courses on tile roofs, as well as other roof systems, refer to Haag Education [www.haageducation.com].)

Are “loose” or “unbonded or not-bonded” tiles caused by wind?

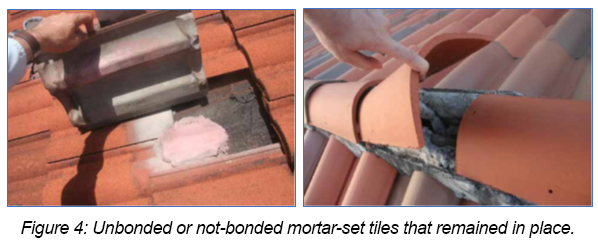

Let’s discuss two common misconceptions related to the TAS 106 frequently encountered during roofing inspections; 1) lift at the butt-ends of mechanically fastened field tiles, and 2) unbonded or not-bonded mortar/adhesive set tiles that remain in place.

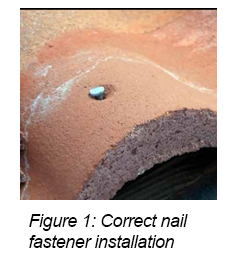

When mechanically fastened tiles are said to be “loose” or exhibit lift of 2 inches or more at the butt-end (tile nose), inspectors often attribute these conditions to wind uplift forces. By the nature of the installation, mechanically attached field tiles can be lifted by hand to some degree, and this is reflected within TAS 106 by the allowable threshold of 2 inches. These tiles are intended to be hung from fasteners, and correct fastener installation entails driving fastener heads nearly flush while providing an adequate gap between the head and the tile surface for thermal movement and to prevent breakage.

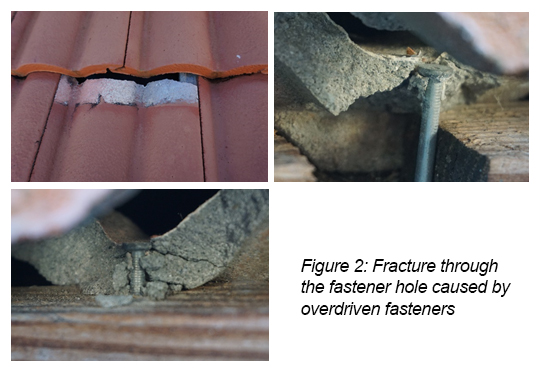

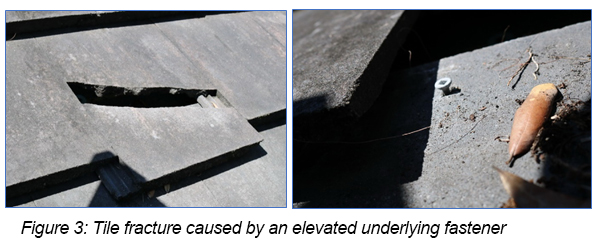

When fasteners are driven tightly against tile surfaces, tiles are prone to fracture during the attachment or as a result of inadequate space for thermal movement. Fasteners can also be under-driven, resulting in an elevated fastener. Depending on the extent of an under-driven fastener, this condition may result in a point load fracture, typically induced by foot traffic.

Unbonded (or not-bonded) mortar-set tiles that remain in place are commonplace and are not the result of wind forces. A bonded roof tile that is broken loose by wind uplift will not remain in place and/or be undisturbed; rather, wind forces great enough to break a bonded tile will also displace or remove the tile from the roof. Tiles that unbonded or never bond to the underlying substrate and remain in place can be caused by a number of factors, including the following: thermal stresses; installation conditions; and/or maintenance activities. Unbonded mortar-set tiles must be periodically reset with new mortar to keep them secure.

Conclusion

Haag has identified the misapplication of the TAS 106 by roof inspectors in the determination of wind-related damage to tile roofing systems. It is Haag’s opinion that this Application Standard is not intended to be used, nor is valid on its own merit, in the determination of whether roof tiles have sustained damage from wind. Per the FBC, TAS 106 is a product application control test performed by a Dade County Approved Testing Agency to confirm adequate tile attachment of tile roof systems within the High-Velocity Hurricane Zones at the time of installation. Frequent use of TAS 106 by inspectors to illustrate unbonded (or not bonded) mortar/adhesive-set tiles, as well as an in-situ lift in excess of 2 inches at the butt-ends of mechanically attached tiles, fails to consider the installation quality of tile roofs, the effects of wind on a structure, and numerous other factors that can contribute to failure of tile roofs. Using the TAS 106 does not give any insight as to whether the roofing system was damaged by wind forces or not. We encourage the reference of this blog within the roofing industry to simplify, understand, and convey the use and importance of TAS 106.

Authors:

Aaron Duba, P.E., is a Forensic Engineer in Tampa, Florida.

John Ellis, P.E., is a Forensic Engineer in Tallahassee, Florida.

Any opinions expressed herein are those of the author(s) and do not necessarily reflect those of Haag Engineering Co., Haag Construction Consulting, Haag Education, or parent company, Haag Global, Inc.