LACK OF SEALANT BOND ON COMP SHINGLES: IS IT WIND DAMAGE?

By Tim Marshall, P.E., Meteorologist, Haag Principal Engineer

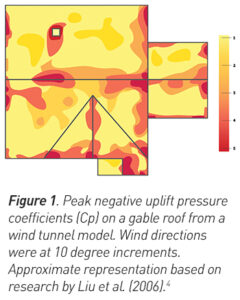

| Wind interacting with a roof is deflected over and around it. As a result, uplift pressures develop on the roof. However, uplift pressures are not uniform and are highest along the windward corners, rakes, eaves, and ridges (Fig. 1). It is at these locations that wind uplift damage initiates especially with asphalt shingles that are not bonded. Wind flow in these areas is quite turbulent. Thus, it is important that the roof covering receive additional anchorage in these high wind uplift regions. The Federal Emergency Management Agency (FEMA 2005) has published guidelines1 on how to attach asphalt shingles in these areas which involve the application of adhesive dollops along the roof edge and between the asphalt shingles in high wind zones.

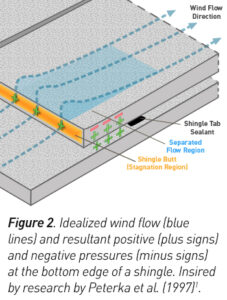

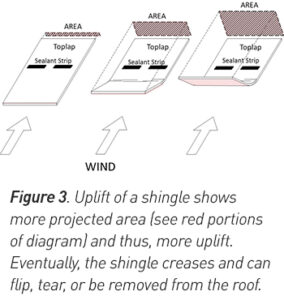

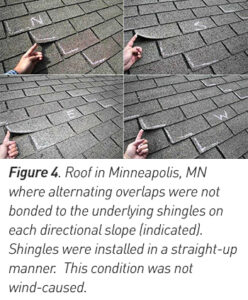

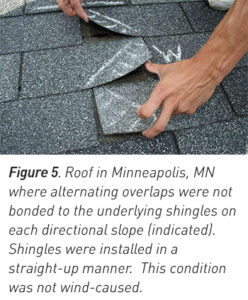

One mechanism of asphalt shingle uplift is specific to the shingle itself. Peterka et al. (1997) 2 and Jones et al. (1999) 3 have shown that wind-induced uplift of shingles can be different from the mechanism that causes uplift on impervious roof sheathing. Due to small dimensions of the shingles and their pervious design, pressure variations across the shingle surfaces can be relatively small. Thus, it is the profile of the shingle that determines the extent of wind uplift. A critical part of the shingle is the region that is cantilevered downslope from the sealant strip (Fig. 2). Wind stagnates at the base of the shingle while aerodynamic uplift occurs on top of the shingle, a situation similar to what occurs on an aircraft wing. The resulting lift can deform the shingle, producing greater projected area and therefore, more lift. Noone and Blanchard (1993) 4 indicated: 1) the quality of fastener installation, 2) the strength of the sealant, and 3) the physical properties of the asphalt shingle (i.e. fastener pull-out strength and stiffness) are critical factors in resisting wind uplift damage. The two most common types of strip asphalt shingles are three-tab and laminated. Both shingle types are comprised of glass-fiber or paper mats that are saturated in hot asphalt and top coated with granules. With three-tab shingles, two joints are cut out of the bottom half of the shingle primarily as a design feature. Laminated shingles have a top laminate and a bottom laminate. The lower portion of the top laminate typically has trapezoidal-shaped cut-outs whereas the bottom laminate is a solid shingle. The bottom laminate is only half the width of the top laminate and is adhered to the lower portion on the back side of the top laminate. The design of the laminated shingle gives the appearance of wood shingles. Both shingle types have sealant strips. A study by this author (2004) after Hurricane Frances showed that three-tab shingles were much more susceptible to wind damage than laminated type shingles. As wind lifts the shingle, it can break the sealant bond. As more surface area is exposed to the wind, there is more uplift. Thus, the shingle eventually creases and can flip, tear, or be removed (Figure 3.) Typically, there are all modes of such failure on a wind damaged roof. The age of damage can be judged by the degree of weathering of the asphalt and condition of exposed fasteners on the underlying shingles. Asphalt turns grey (oxidizes) as it become exposed to the weather changing from glossy black to dull grey in a matter of months. Longer time is needed to create rust on exposed fasteners. Therefore, new and old damage can be ascertained by closely studying the damaged areas. Roof inspectors must be wary that the lack of sealant bond does not necessarily indicate wind damage has occurred. Shingles frequently are not bonded to the roof where they overlap an adjacent shingle. Poor adhesion of the sealant strip in combination with cyclic thermal expansion and contraction along the long dimension of the shingle causes the lack of bond condition. Eventually, dirt and debris render the seal ineffective. The author has found this condition on roofs around the U.S., and not just in hurricane prone regions. Depending on your location, shingles are installed either in a diagonal manner or vertically in a straight-up manner. Therefore, the pattern of the shingle overlaps will depend on how the shingles are installed. Shingles installed in a racking or straight-up pattern typically have alternating overlaps not bonded to the underlying shingles. By comparison, shingles installed diagonally typically have left or right overlaps not bonded to the underlying shingles. Usually, overlaps that are not bonded can be found on each directional slope. Wind does not come from multiple directions with just enough force to unbond the shingle overlaps on different slopes. Refer to Figures 4 and 5. In summary, wind damage is obvious with a combination of uplifted and creased, flipped, and removed shingles. Flying debris impact might damage other shingles. Wind damage typically is concentrated on the windward sides of a roof, especially along eaves, ridges, and tops of valleys. Shingles with little or no bond are especially prone to being lifted and damaged by wind. However, the lack of shingle bond alone does not constitute wind damage. ***** 1 Federal Emergency Management Agency, 2005: Asphalt shingle roofing for high-wind regions, Tech. Fact Sheet 20, 2 pp. [Available online at: http://www.flash.org/resources/files/HGCC_Fact20.pdf.] 2Peterka, J.A., Cermak, J.E., Cochran, L.S., Cochran, B.C., Hosoya, N., Derickson, R.G., Harper, C., Jones, J. and Metz, B., 1997: “Wind Uplift Model for Asphalt Shingles., Jour. of Architectural Engineering, Amer. Soc. of Civil Engineers, Vol. 3, No. 4, 147-155. [Available online at: http://cedb.asce.org/cgi/WWWdisplay.cgi?9705505.] 3Jones, J., R. Metz, C. W. Harper, 1999: ARMA wind uplift load model for assessing asphalt shingle performance. Proc. Fourth Intl. Symposium on Roofing Tech., Gaithersburg, MD, 180-184. [Available online at: http://docserver.nrca.net/pdfs/technical/5832.pdf.] 4Noone, M. J., and W. K. Blanchard, 1993: Asphalt shingles – A century of success and improvement, 10th Conf. on Roofing Technology, Gaithersburg, MD, 23-33. [Available online at: http://docserver.nrca.net/pdfs/technical/1817.pdf.] 5Liu, Z., D. O. Prevatt, L. D. Aponte, T. A. Reinhold, K. R. Gurley, and F. J. Masters, 2006: Wind load determination using field data and wind tunnel studies on residential buildings, Fourth LACCEI International Latin American and Caribbean Conf. for Engineering and Technology, 10 pp. [Available online at: http://www.davidoprevatt.com/wp…/uploads/2008/…/whm197_prevatt-laccei-06.pdf.] By Tim Marshall, P.E., Meteorologist, Haag Engineer Tim Marshall is a structural engineer and meteorologist. He has served as a Haag Engineer since 1983, assessing damage to 1000s of structures (particularly damage caused by wind and other weather phenomena). He has written numerous articles, presented countless lectures, and appeared on dozens of television programs in order to share his extensive knowledge re: storms and the resultant damage. He is a primary author of many Haag Education materials, including the Haag Certified Inspector-Wind Damage course. He is also a pioneering storm chaser and was editor of Storm Track magazine. |

|